A Strategic Choice Between 2-Plate and 3-Plate Molds

Samgo Demystifies Mold Design: A Strategic Choice Between 2-Plate and 3-Plate Molds

In the precision-driven world of plastic injection molding, the choice of mold type is one of the most fundamental and impactful decisions an engineer can make. It directly influences part quality, production efficiency, and overall project cost. As a leader in injection molding solutions, Samgo is leveraging its extensive expertise to guide manufacturers through the critical selection process between the two most common mold types: the versatile 2-plate mold and the sophisticated 3-plate mold.

Understanding the distinct advantages, limitations, and ideal applications of each system is paramount for optimizing manufacturing outcomes. “The decision between a 2-plate and a 3-plate mold isn’t about which is better in a vacuum; it’s about which is perfectly suited for the part’s geometry, material, and production volume,” explains a Senior Mold Engineer at Samgo. “Making the right choice at the design stage saves significant time and cost down the line.”

The Workhorse of the Industry: The 2-Plate Mold

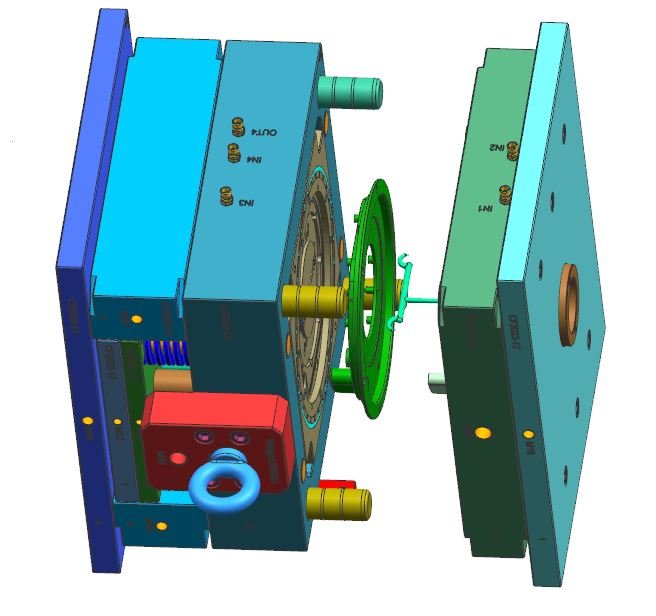

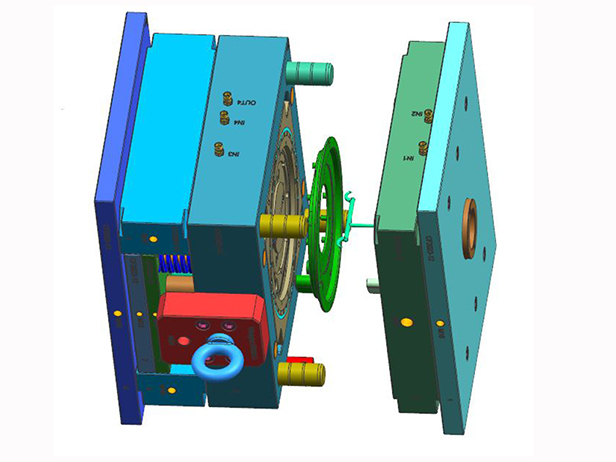

The 2-plate mold, as the name implies, consists of two primary plates: the cavity side (fixed to the machine’s platen) and the core side (which moves during ejection). It is the most common, straightforward, and cost-effective mold design used across the industry.

How it Works: During the injection cycle, the two plates are clamped together to form the part cavity. After the plastic cools and solidifies, the plates separate, and ejector pins push the finished part, along with its attached runner system, out of the mold.

Advantages of 2-Plate Molds:

- Lower Initial Cost: With a simpler design featuring fewer components and plates, 2-plate molds are less expensive to manufacture.

- Robust and Durable: The straightforward construction generally leads to a longer mold life with less maintenance.

- Faster Cycle Potentials: The simpler opening and ejection mechanism can sometimes allow for quicker cycle times.

- Easier Maintenance: Troubleshooting and maintenance are less complex due to the uncomplicated design.

Disadvantages of 2-Plate Molds:

- Limited Gating Options: Gates are typically located on the part’s perimeter, which can lead to visible gate marks.

- Manual Runner Separation: The solidified runner system is ejected with the part, requiring an additional, often manual, step for separation, which adds to unit cost and can interrupt automated lines.

- Potential for Material Waste: For multi-cavity molds, the runner system can be substantial, leading to higher material scrap rates.

The Precision Specialist: The 3-Plate Mold

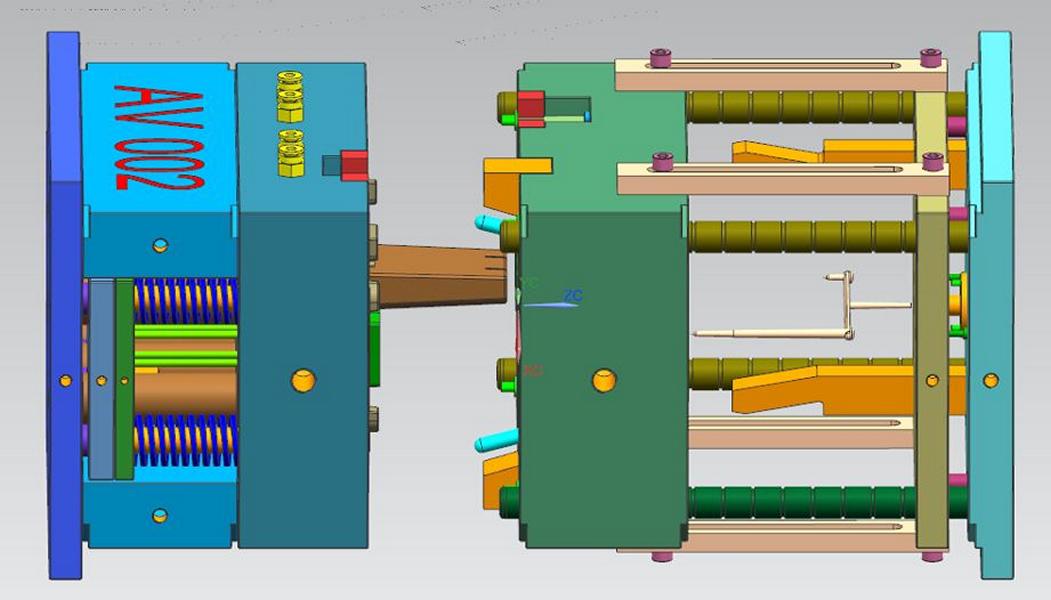

The 3-plate mold introduces a third, intermediate plate that moves independently, allowing the mold to open at two separate parting lines. This complex design is engineered for specific production requirements that a 2-plate mold cannot efficiently meet.

How it Works: The mold opens in two stages. First, the intermediate plate pulls away from the cavity plate, automatically severing the gate and ejecting the runner system through a dedicated channel. Second, the main plates separate, allowing the finished, gate-free part to be ejected.

Advantages of 3-Plate Molds:

- Automatic Runner Separation: This is a key benefit for automation, as the parts and runners are ejected separately, allowing for fully unattended production.

- Central Gating Flexibility: Gates can be located at the center of the part, which is ideal for multi-cavity layouts and provides better flow for certain geometries. This also results in less visible gate marks.

- Reduced Material Waste: While the runner still exists, its automated removal and often smaller size (due to more efficient layouts) can reduce handling and potential waste.

- Superior for Certain Geometries: Essential for parts where side-gates are not permissible for aesthetic or functional reasons.

Disadvantages of 3-Plate Molds:

- Higher Initial Cost: The added complexity of plates, mechanisms, and controls makes them more expensive to design and build.

- Increased Maintenance: More moving parts and intricate mechanisms mean a higher potential for wear and tear, requiring more meticulous maintenance.

- Longer Cycle Times: The sequence of a double opening can sometimes add seconds to each cycle, impacting overall output.

- Reduced Mold Strength: The mold’s structural integrity can be slightly compromised due to the need for additional plates and spaces, which may not be suitable for all materials or high-pressure applications.

Making the Strategic Choice: A Samgo Perspective

The engineers at Samgo emphasize that the choice hinges on a careful analysis of project requirements. The following table provides a clear, at-a-glance comparison to aid in the decision-making process.

| Feature | 2-Plate Mold | 3-Plate Mold |

|---|---|---|

| Initial Cost | Lower | Higher |

| Complexity | Simple | Complex |

| Gating Location | Part Perimeter | Part Center or Perimeter |

| Runner Separation | Manual | Automatic |

| Ideal for Automation | Less Suitable | Excellent |

| Material Waste | Potentially Higher | Potentially Lower |

| Cycle Time | Generally Faster | Potentially Slower |

| Mold Life & Maintenance | More Robust, Easier | More Fragile, Complex |

| Best For | High-volume, cost-sensitive parts, where gate vestige is not a critical issue. | Automated production, parts requiring central or hidden gates, complex multi-cavity layouts. |

“At Samgo, we don’t just build molds; we engineer solutions,” the Senior Engineer concludes. “During our Design for Manufacturability (DFM) phase, we perform a thorough analysis of our client’s part design, production volume, and quality expectations. We then provide a data-driven recommendation on mold type, ensuring the investment aligns perfectly with their long-term production and financial goals. Whether it’s the economical workhorse 2-plate or the automated specialist 3-plate, our clients can be confident they are getting the optimal tool for their specific application.”

This deep expertise in fundamental mold design principles allows Samgo to deliver not just parts, but value, efficiency, and reliability to its global clientele.