- Samgomould

- 19 Ene 2026

Optimizing Plastic Part Production: An In-Depth Look at Injection Mold DFM Report Analysis

1. Introduction: The Critical Role of DFM in Moldeo por inyección

In the competitive world of plastic part manufacturing, the difference between a profitable, high-quality product and a problematic, costly one is often determined long before the first mold is ever cut. This decisive phase is governed by Design for Manufacturability (DFM), a proactive engineering practice aimed at optimizing a part design for efficient, cost-effective, and robust production. At the heart of this process lies the DFM Report—a comprehensive analytical document that acts as a collaborative blueprint between part designers and mold makers.

An Injection Mold DFM report is not merely a checklist; it is a detailed forensic analysis and a roadmap for success. It systematically evaluates a part’s 3D CAD model, identifying potential manufacturing hurdles, predicting defects, and prescribing optimizations to ensure the mold is built right the first time. This article delves into the crucial components of a best-in-class DFM report analysis, illustrating how it de-risks projects, saves significant time and money, and elevates final part quality.

2. Core Components of a Comprehensive DFM Analysis

A thorough DFM report breaks down the design into manufacturability pillars. Each section provides targeted feedback.

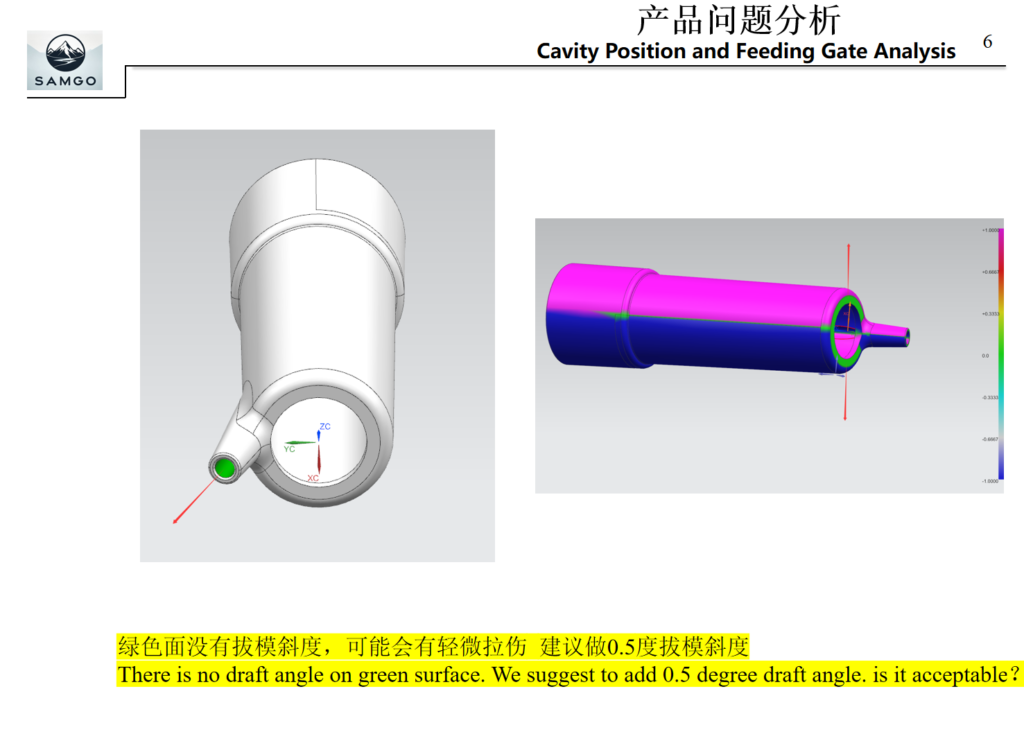

2.1. Draft Angle Analysis

Perhaps the most fundamental rule of injection molding, draft—the slight taper applied to surfaces parallel to the mold opening direction—is essential for part ejection. A DFM report meticulously measures the draft on every vertical face, flagging areas with insufficient angle (typically less than 1 degree, though it varies by material and texture). Without adequate draft, the part can stick, causing drag marks, deformation, or even catastrophic ejection failure during the molding cycle.

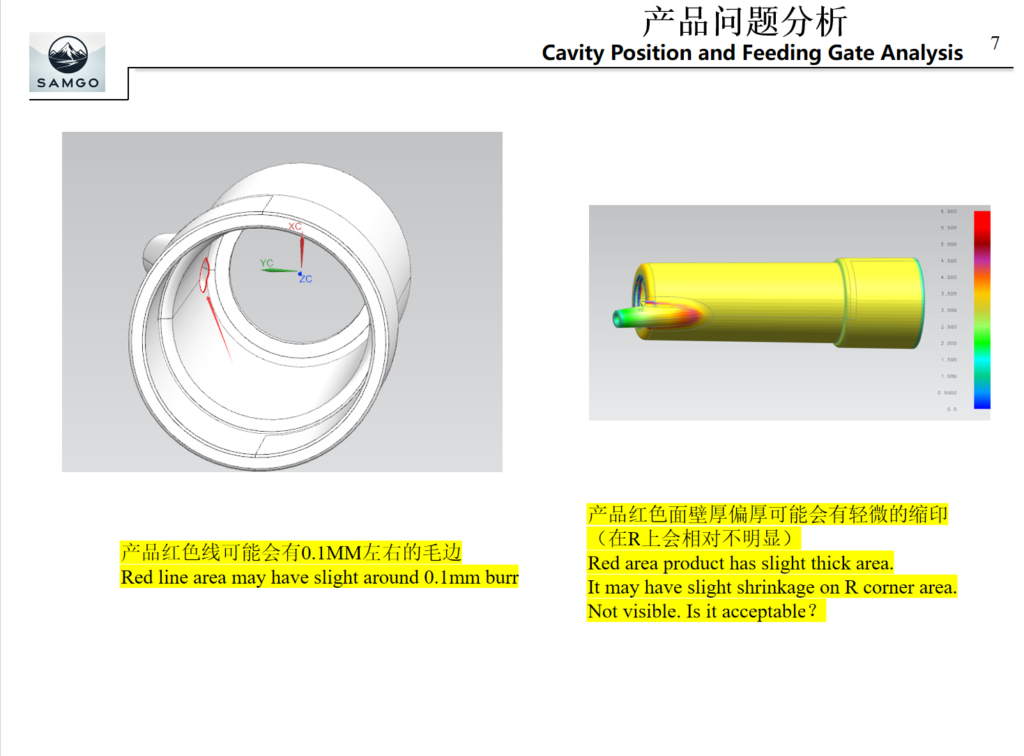

2.2. Wall Thickness Uniformity

Consistent wall thickness is the cornerstone of high-quality molding. A DFM report uses thickness analysis tools to create a “heat map” of the part. Thick sections (or “ribs” at junctions) are highlighted as they cool slower, leading to sinks, voids, and internal stresses. Thin areas may not fill properly, causing short shots. The report recommends strategies like coring out thick areas and implementing gradual transitions (maximum 25% change in thickness at intersections).

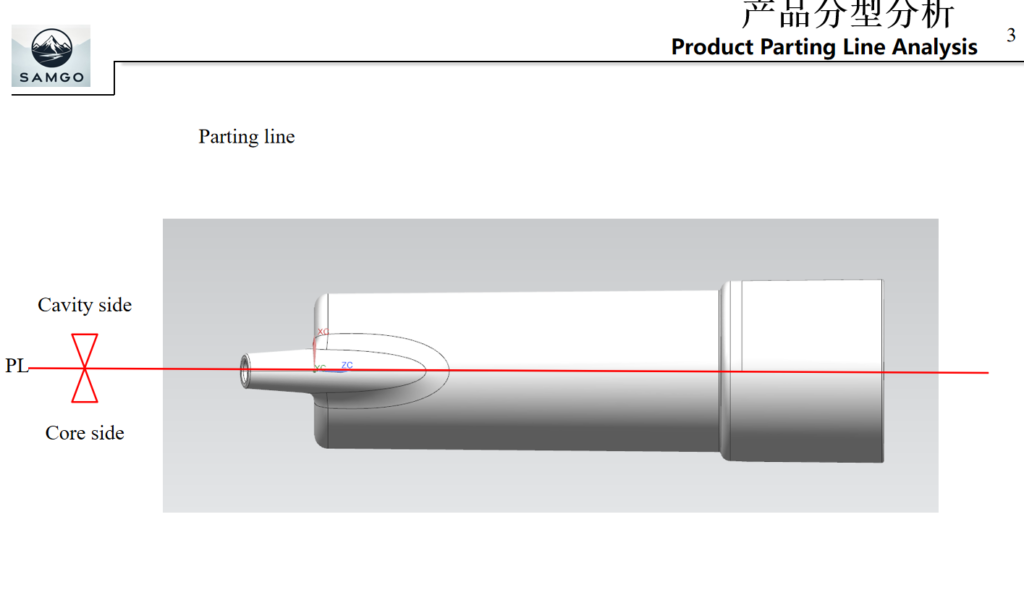

2.3. Undercut & Parting Line Evaluation

Undercuts are features that prevent the part from being ejected directly from the mold. The DFM report identifies all undercuts and classifies them. For each, it proposes the most cost-effective solution: Can the design be slightly modified to eliminate it? If not, should a slider, lifter, or hand-loaded insert be used? This analysis directly impacts mold complexity and cost. Simultaneously, the optimal parting line—the seam where mold halves meet—is proposed to minimize undercuts and ensure aesthetic quality.

2.4. Rib Design, Boss Design, and Sink Risk Assessment

Ribs and bosses are common but tricky features. The DFM report provides specific geometry rules: ribs should be 50-60% of the adjacent wall thickness, bosses should be cored at the base and connected via ribs to walls. Using sink analysis software, the report predicts and visually maps potential sink marks over ribs and bosses, allowing for pre-emptive corrective action in the design phase.

3. Advanced Analysis: Gate Location, Filling, Cooling, and Warpage

Modern DFM leverages sophisticated Mold Flow Simulation (or CAE analysis) to move beyond geometric checks and into the realm of predicting physical behavior.

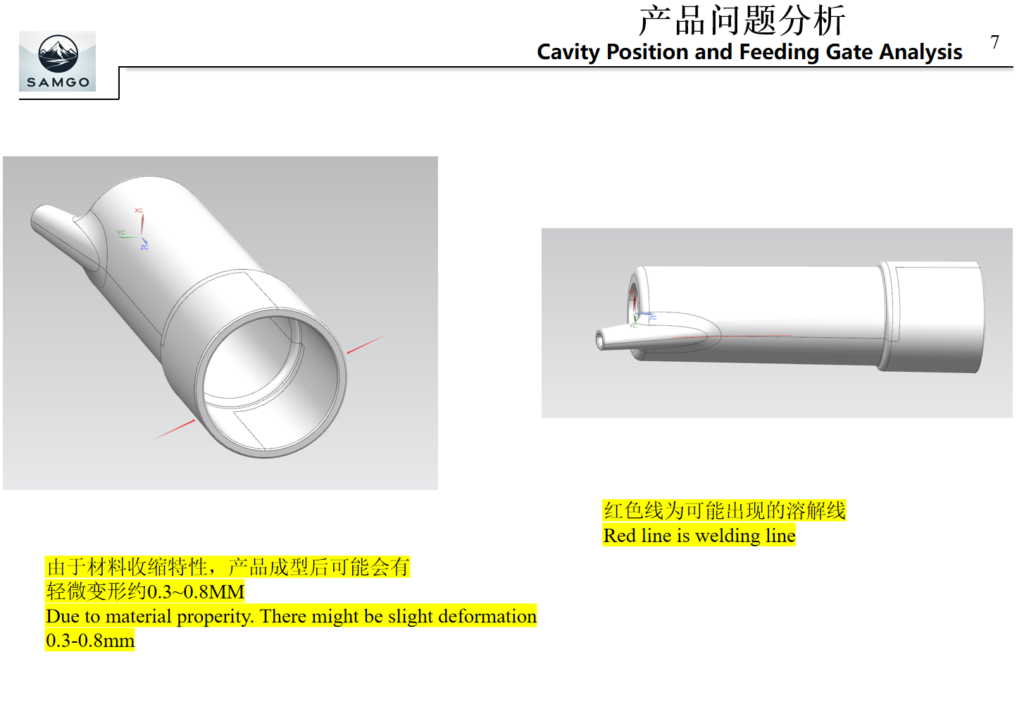

3.1. Gate Location & Filling Simulation

The gate is where molten plastic enters the cavity. Its location is critical. The DFM report includes simulation results that model the plastic flow from candidate gate locations. It identifies potential issues like weld lines (where flow fronts meet, creating a weak point) and air traps. The analysis recommends the optimal gate location to ensure balanced filling, minimize cosmetic defects, and place weld lines in non-critical areas.

3.2. Cooling & Warpage Analysis

Up to 80% of the molding cycle is cooling. An efficient, uniform cooling system is vital. The DFM report analyzes the proposed cooling channel layout, identifying hot spots where cooling is insufficient. Warpage simulation predicts how differential shrinkage—caused by uneven cooling or material orientation—will distort the part. The report suggests cooling line adjustments, part design tweaks, or material selection changes to mitigate warpage and ensure the part meets critical flatness or assembly tolerances.

4. Material, Tolerances, and Cost Implications

The DFM report contextualizes all findings within the project’s practical constraints.

Material Review: It confirms the selected resin is suitable for the part’s function, geometry, and required finish. It may highlight potential issues like low flow length for thin walls or high shrinkage for tight tolerances.

Tolerance Benchmarking: The report assesses the feasibility of critical dimensions against standard and precision molding capabilities, preventing unmanufacturable specifications.

Cost Drivers Summary: This is a crucial deliverable. The report explicitly links design features to cost, e.g., “Each side-action slider adds approximately X% to the mold base cost and Y% to maintenance.” It provides designers with clear data to make informed trade-off decisions between ideal design and optimal cost.

5. Conclusion: The DFM Report as a Strategic Partnership Document

The culmination of the DFM process is more than a PDF; it’s the foundation for collaboration. A world-class report presents findings clearly with annotated images, 3D views, and simulation data, but more importantly, it provides actionable recommendations. For every potential problem flagged, it offers one or more practical solutions, ranking them by impact on cost, quality, and timeline.

Investing in a detailed DFM report analysis is a strategic decision that pays exponential returns. It transforms the mold fabrication process from a risky gamble into a predictable engineering procedure. By front-loading the problem-solving, companies avoid the devastating cycle of mold rework, delayed launches, and production line bandaids. In essence, a comprehensive DFM report doesn’t just analyze a design—it guarantees a smoother, faster, and more profitable journey from concept to high-volume production.