PC injection molding

- Home

-  / Material /

- PC injection molding

Polycarbonate (PC) Injection Moulding: Mastering the High-Performance Engineering Plastic

1. Introduction: The Transparent Engineering Titan

Polycarbonate (PC) stands as one of the most versatile and technically demanding engineering thermoplastics, renowned for its exceptional combination of optical clarity, impact resistance, and thermal stability. First commercially produced in the 1950s, PC has evolved from a specialty material to an industrial workhorse, finding critical applications where performance cannot be compromised. Unlike commodity plastics, PC injection moulding represents the pinnacle of precision processing, requiring meticulous attention to material science, process parameters, and tooling design to unlock its full potential.

This comprehensive guide explores the intricate world of PC injection moulding, from its molecular structure to advanced processing techniques. We will examine why PC is the material of choice for applications ranging from medical life-saving devices to aerospace components, and how mastering its processing challenges can yield products of extraordinary performance and reliability.

2. Material Science: Understanding the Polycarbonate Molecule

Chemical Structure and Synthesis

Polycarbonate derives its name from the carbonate groups (–O–(C=O)–O–) in its backbone, typically synthesized from bisphenol-A (BPA) and phosgene via interfacial polymerization or melt transesterification. This structure creates unique characteristics:

Key Structural Elements:

Aromatic Rings: Provide rigidity and high glass transition temperature (Tg ≈ 145-150°C)

Carbonate Linkages: Offer some chain flexibility and chemical functionality

Methyl Groups: Influence chain packing and free volume

Material Grades and Their Specializations:

| Grade Type | Key Characteristics | Applications |

|---|---|---|

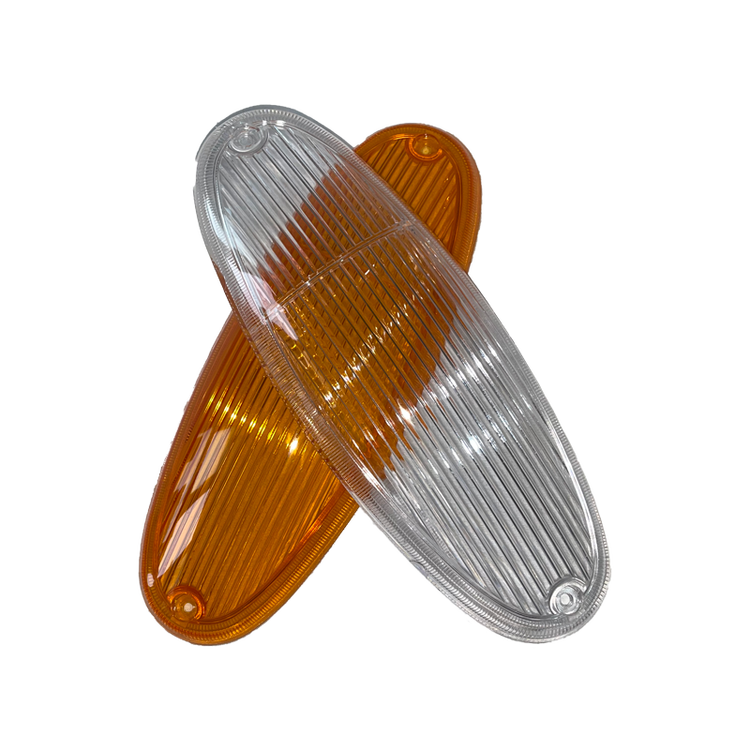

| Optical Grade | 90%+ light transmission, low haze | Lenses, optical discs, display covers |

| Medical Grade | USP Class VI, ISO 10993 compliant | Surgical instruments, drug delivery devices |

| Flame Retardant | UL94 V-0/V-2 ratings, halogen-free options | Electrical enclosures, aviation interiors |

| Glass-Filled | 10-40% glass fiber reinforcement | Structural components, automotive parts |

| Impact Modified | Enhanced low-temperature toughness | Protective equipment, safety components |

| FDA Food Contact | Compliance with food safety regulations | Water bottles, food processing equipment |

Physical Properties Overview:

Density: 1.20-1.22 g/cm³

Refractive Index: 1.584 (excellent optical properties)

Tensile Strength: 55-75 MPa

Notched Izod Impact: 600-850 J/m (exceptionally high)

Heat Deflection Temperature: 130-140°C @ 1.82 MPa

Water Absorption: 0.15-0.35% (24h immersion)

3. Material Handling: The Critical Pre-Processing Phase

The Imperative of Proper Drying

PC is extremely hygroscopic, absorbing up to 0.35% moisture at equilibrium. Improper drying leads to irreversible molecular degradation:

Drying Specifications:

Target Moisture: <0.02% (200 ppm) for optical grades; <0.04% for general purpose

Drying Temperature: 120°C for standard grades; 135°C for high-heat grades

Drying Time: Minimum 4-6 hours; thick pellets may require 8+ hours

Dew Point: -30°C or lower (desiccant dryers recommended)

Hopper Management: Closed-loop drying hoppers with 1-2 hour residence time

Consequences of Insufficient Drying:

Hydrolytic Degradation: Water reacts with carbonate links, reducing molecular weight

Molecular Weight Drop: Directly correlates with impact strength loss

Visual Defects: Splay marks, silver streaks, bubbles

Mechanical Property Loss: Up to 80% reduction in impact strength possible

Regrind Management Strategy:

Maximum Regrind: 20-25% for critical applications

Thermal History Monitoring: Each heat cycle reduces molecular weight

Separate Drying: Regrind often requires longer drying times

Testing Protocol: Regular MFI testing to monitor degradation

4. Injection Moulding Machine Configuration for PC

Machine Selection Criteria:

Clamp Capacity: 3-6 tons per square inch of projected area

Injection Unit: Sized for 40-80% of machine shot capacity

Drive Type: Electric or hybrid preferred for precise control

Screw Design Requirements:

Type: General purpose or gradual compression screw

L/D Ratio: 20:1 to 24:1 (longer for better melt homogeneity)

Compression Ratio: 2.0:1 to 2.5:1

Check Valve: Sliding ring type with minimal dead space

Screw Tip: Mixing elements recommended for color dispersion

Barrel and Nozzle Specifications:

Barrel Zones: Minimum 4 zones with PID temperature control

Nozzle Type: Open nozzle standard; shut-off for drool prevention

Temperature Control: ±2°C accuracy required

Capacity: Screw diameter should provide adequate shear heating

5. Processing Parameters: Precision Control Requirements

Temperature Settings by Application:

| Application | Melt Temperature | Mould Temperature | Special Considerations |

|---|---|---|---|

| Optical Parts | 300-320°C | 80-110°C | Highest temperatures for clarity |

| Thin-Wall Parts | 310-330°C | 70-90°C | Fast injection needed |

| Structural Parts | 290-310°C | 60-80°C | Lower temps for dimensional stability |

| Medical Components | 300-315°C | 70-90°C | Strict temperature documentation |

Zone-by-Zone Temperature Profile:

Rear Zone: 260-280°C (gentle preheating)

Middle Zones: 280-310°C (gradual temperature rise)

Front Zone: 300-320°C (final melt homogenization)

Nozzle: 300-320°C (matched to front zone)

Injection Phase Parameters:

Injection Speed: Fast to very fast (prevents premature freezing)

Injection Pressure: 800-1500 bar (adjust based on flow length)

Boost/Pack Switch: 95-98% cavity fill (critical for pressure control)

Holding/Packing Phase Strategy:

Pressure: 50-70% of injection pressure

Time: Until gate freeze (typically 5-20 seconds)

Profile: Multiple-stage pressure decay often beneficial

Cooling and Cycle Optimization:

Cooling Time: 40-70% of total cycle (depends on wall thickness)

Ejection Temperature: Below 100°C (to prevent stress marks)

Cycle Time: Typically 40-120 seconds

6. Tooling Design Excellence for PC

Mould Material Selection:

Production Moulds: H13, S7, or stainless steel (420SS or 440C)

Surface Hardness: 48-52 HRC minimum

Cavity Polish: SPI A-1 or better for optical parts

Corrosion Protection: Chrome plating or nitriding recommended

Runner System Design:

Full Round Runners: 6-10mm diameter minimum

Hot Runners: Externally heated with precise temperature control

Gate Types:

Tab Gates: For reducing jetting

Diaphragm Gates: For cylindrical parts

Direct Hot Tips: For cosmetic parts

Cooling System Criticality:

Channel Design: Conformal cooling preferred for complex parts

Temperature Control: ±2°C across mould surface

Circuit Layout: Separate circuits for cores and cavities

Coolant Flow: Turbulent flow for maximum heat transfer

Venting Specifications:

Vent Depth: 0.015-0.025mm (shallower than many materials)

Vent Width: 6-12mm

Vent Placement: Every 25-50mm along parting line

Special Vents: At weld lines and end-of-fill areas

Ejection System Design:

Ejector Pins: Larger diameter pins for lower surface pressure

Stripper Plates: For thin-walled cylindrical parts

Air Ejection: For optical parts requiring mark-free surfaces

7. Part Design Guidelines for Polycarbonate

Wall Thickness Principles:

General Range: 1.5-4.0mm

Optimal Thickness: 2.5-3.0mm for best flow/strength balance

Uniformity: Critical (maximum 15% variation)

Thick Sections: Core out to prevent sink marks and reduce cycle time

Rib Design Strategy:

Rib Thickness: 40-50% of adjacent wall

Rib Height: Maximum 3 times wall thickness

Rib Spacing: Minimum 2.5 times wall thickness

Draft Angles: 1-2° per side

Corner and Transition Design:

Internal Radii: 0.5-1.0 times wall thickness

External Radii: Internal radius plus wall thickness

Tapered Transitions: For thickness changes >25%

Draft Angle Requirements:

Optical Surfaces: 0.5-1° per side minimum

Textured Surfaces: 3° per side plus 1° per 0.025mm texture depth

Deep Draw Parts: Additional 0.5-1° per 25mm depth

Living Hinge Design (PC-specific):

Thickness: 0.25-0.50mm

Width: 1.5-3.0mm

Radii: Generous radii at hinge ends

Orientation: Perpendicular to flow direction

8. Troubleshooting: Addressing PC-Specific Challenges

Critical Defects and Solutions

| Defect | Root Causes | Corrective Actions |

|---|---|---|

| Splay/Silver Streaks | Moisture contamination, overheated melt | Verify drying (<0.02%), reduce melt temp, check check valve |

| Bubbles/Voids | Moisture, excessive holding pressure, short packing | Improve drying, reduce holding pressure, increase pack time |

| Weld Lines | Low melt temp, slow injection, poor gate location | Increase temp 10-20°C, increase speed, relocate gates |

| Residual Stress | Rapid cooling, high packing pressure, improper ejection | Increase mould temp, reduce pack pressure, optimize ejection |

| Chemical Crazing | Stress + chemical exposure (IPA, cleaners) | Reduce stress through design/process, avoid chemical exposure |

| Yellowing | Thermal degradation, excessive regrind, UV exposure | Lower melt temp, reduce regrind %, add UV stabilizers |

| Jetting | Gate too small, injection too fast, cold mould | Enlarge gate, use tab gate, increase mould temperature |

| Sticking | Undercuts, insufficient draft, high mould temp | Add draft, polish core, lower mould temperature |

Material Degradation Monitoring:

Melt Flow Index: Regular testing (increase indicates degradation)

Color Measurement: Spectrophotometer for yellowing detection

Impact Testing: Periodic checks for property retention

FTIR Analysis: For chemical structure verification

9. Post-Processing and Secondary Operations

Stress Relief Annealing:

Necessity: Critical for parts with residual stress or chemical exposure

Temperature: 125-135°C (10-20°C below Tg)

Time: 1-4 hours depending on wall thickness

Cooling Rate: 1-2°C per minute to room temperature

Machining and Finishing:

Machinability: Good with sharp tools and proper cooling

Drilling/Tapping: Use positive rake angles and peck drilling

Polishing: Successive grits to restore optical clarity

Coatings: Hard coats for abrasion resistance (silicone-based)

Joining and Assembly:

Solvent Bonding:

Solvents: Methylene chloride, ethylene dichloride

Process: Capillary action with proper fixturing

Strength: 80-100% of base material

Ultrasonic Welding:

Energy directors required

Near-field welding (<6mm) preferred

Adhesive Bonding:

Epoxies, cyanoacrylates, or UV-cure adhesives

Surface treatment may be required

Decorative Processes:

Painting: Requires adhesion promoters

Metallization: Vacuum metallization for reflective surfaces

Printing: Pad printing, screen printing, or digital printing

Laser Marking: High contrast marks possible

10. Advanced Processing Techniques for PC

Multi-Material/Overmoulding:

PC/TPU Combinations: For soft-touch grips on rigid substrates

PC/PC Combinations: For two-shot color effects

Mould Requirements: Precise temperature control for each material

In-Mould Decoration (IMD):

Film Types: PC, PET, or multilayer films

Applications: Automotive interiors, appliance panels

Challenges: Film handling, adhesion, optical clarity maintenance

Microcellular Foam Moulding:

Benefits: Weight reduction (5-30%), reduced sink marks

Challenges: Surface quality, strength reduction

Applications: Thick structural parts, large panels

Injection-Compression Moulding:

Benefits: Lower stress, better optical properties

Proceso: Partial injection followed by mould compression

Applications: Large optical components, lenses

Clean Room Moulding:

Requirements: ISO Class 7 or better

Applications: Medical, optical, data storage

Considerations: Material handling, machine enclosures, personnel training

11. Quality Control and Material Testing

Process Control Parameters:

Melt Temperature: Infrared pyrometer verification

Mould Temperature: Surface probes at multiple locations

Cushion Consistency: ±0.5mm variation maximum

Cycle Time: Statistical process control charts

Material Characterization Tests:

Rheological:

Melt Flow Rate (ASTM D1238)

Capillary rheometry for viscosity curves

Mechanical:

Tensile (ASTM D638)

Impact (ASTM D256, D3763)

Flexural (ASTM D790)

Thermal:

DSC for Tg and crystallinity

TGA for thermal stability

HDT (ASTM D648)

Optical:

Haze and transmission (ASTM D1003)

Refractive index

Yellowness index (ASTM D1925)

Part Validation Testing:

Dimensional: CMM with temperature-controlled environment

Optical: Interferometry for surface quality

Stress Analysis: Polarized light or photoelastic methods

Environmental: Thermal cycling, humidity exposure, chemical resistance

12. Industry Applications and Case Studies

Automotive Industry:

Headlamps: Complex optics requiring clarity and heat resistance

Glazing: Sunroofs, side windows (weight reduction vs. glass)

Components: Connectors, sensors, interior trim

Medical Technology:

Surgical Instruments: Autoclavable, transparent

Drug Delivery: Transparency for fluid monitoring

Equipment Housings: Impact resistance and cleanability

Electronics and Electrical:

Connectors: UL94 V-0 requirements

Enclosures: EMI shielding options

Displays: Touch screen covers, light guides

Aerospace and Defense:

Windows and Canopies: Impact resistance and optical quality

Components: Lightweight structural parts

Protective Gear: Visors, shields

Consumer Products:

Eyewear: Prescription lenses, safety glasses

Appliances: Transparent doors, components

Packaging: Medical, high-value product packaging

13. Sustainability and Future Directions

Recycling Challenges and Solutions:

Mechanical Recycling: Limited by thermal degradation

Chemical Recycling:

Hydrolysis: Back to BPA and carbonate sources

Glycolysis: For polyol production

Pyrolysis: For chemical feedstocks

Closed-Loop Systems: Developing for specific applications

Bio-based and Alternative Materials:

BPA-Free PC: Isosorbide-based polymers

Bio-PC: Partially bio-based monomers

Performance: Similar optical and mechanical properties

Energy Efficiency Initiatives:

All-Electric Machines: Precise control for energy savings

Heat Recovery: From cooling systems

Process Optimization: Reduced cycle times through simulation

Emerging Technologies:

Nano-composites: Enhanced properties at lower weight

Self-healing PC: Microcapsule technology

Smart PC: Integrated sensors or functional additives

14. Conclusion: The Clear Choice for Demanding Applications

Polycarbonate injection moulding represents a sophisticated intersection of material science and precision engineering. Its successful processing demands respect for the material’s characteristics—particularly its hygroscopic nature and sensitivity to thermal history—combined with meticulous attention to every aspect of the manufacturing process.

The future of PC lies in balancing its exceptional performance with growing sustainability demands. Advances in recycling technologies, bio-based alternatives, and processing efficiency will ensure PC remains relevant in an increasingly environmentally conscious market. For manufacturers, the key to success with PC is developing deep process knowledge, implementing rigorous quality control, and maintaining flexibility to adopt new technologies and methods.

As applications become more demanding—whether in thinner walls, higher optical clarity, or enhanced sustainability profiles—PC injection moulding professionals must continue to push the boundaries of what is possible with this remarkable engineering material.