PEEK injection molding

- Home

- / Material /

- PEEK injection molding

PEEK Injection Moulding: Mastering High-Performance Polymer Processing

1. Introduction: The Pinnacle of Engineering Plastics

Polyether ether ketone (PEEK) represents the apex of high-performance thermoplastics, combining exceptional mechanical properties, thermal stability, and chemical resistance in ways that no other polymer can match. First commercialized in the 1980s, this semi-crystalline super-engineering polymer has become indispensable in applications where failure is not an option – from deep-sea oil exploration to aerospace propulsion systems and life-sustaining medical implants. With its ability to withstand continuous service temperatures up to 260°C (500°F) while maintaining structural integrity, PEEK injection moulding stands as one of the most demanding and technically sophisticated manufacturing processes in the polymer industry.

This comprehensive guide explores the intricate world of PEEK injection moulding, examining the material’s unique characteristics, specialized processing requirements, and the exacting standards necessary to produce components that routinely operate in extreme environments. We will uncover why PEEK commands premium pricing yet delivers unparalleled value in critical applications, and how advances in processing technology continue to expand its boundaries in demanding sectors.

2. Material Science: Understanding PEEK’s Exceptional Properties

Chemical Architecture:

PEEK belongs to the PAEK (polyaryletherketone) family, characterized by an alternating structure of aromatic rings connected by ketone and ether functional groups. This molecular architecture provides:

Key Structural Features:

Aromatic Backbone: Provides thermal stability and rigidity

Ketone Groups: Contribute to high temperature resistance

Ether Linkages: Offer some chain flexibility

Crystalline Structure: 30-35% crystallinity typical in molded parts

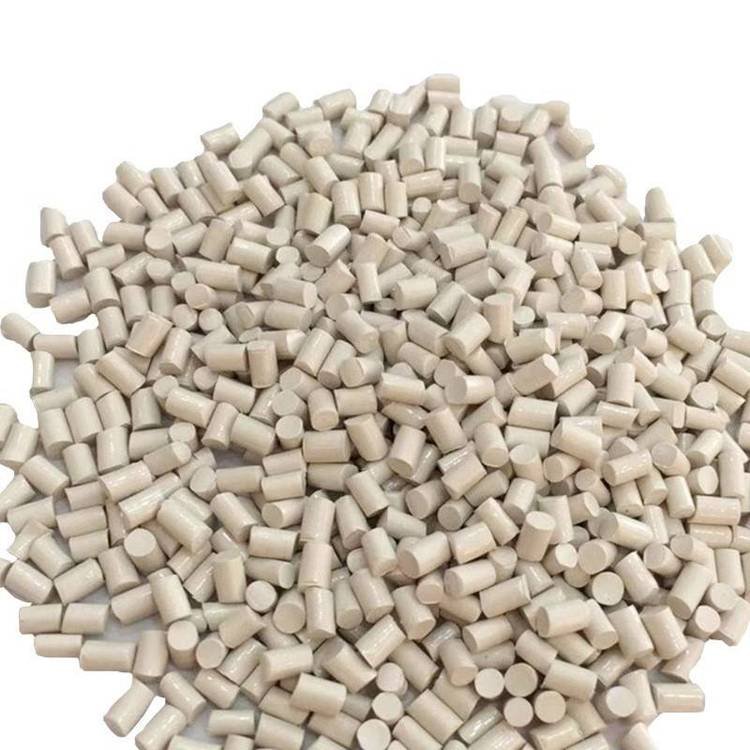

Material Grades and Modifications:

| Grade Type | Key Characteristics | Typical Applications |

|---|---|---|

| Virgin PEEK | Unfilled, natural color | Medical implants, semiconductor |

| 30% Glass-Filled | Enhanced stiffness, dimensional stability | Structural components, bearings |

| 30% Carbon-Filled | Superior strength, conductivity | Aerospace, automotive racing |

| PTFE-Filled | Reduced friction, wear resistance | Bushings, seals, bearings |

| Carbon Fiber Reinforced | Highest strength-to-weight ratio | Aerospace structures |

| Medical Grade | ISO 10993, USP Class VI compliant | Spinal implants, dental components |

Exceptional Property Matrix:

| Property | Value Range | Comparison Advantage |

|---|---|---|

| Continuous Service Temp | 260°C (500°F) | Highest among thermoplastics |

| Tensile Strength | 90-100 MPa (unfilled) | Comparable to aluminum |

| Flexural Modulus | 3.6-4.0 GPa (unfilled) | Stiff engineering performance |

| HDT @ 1.82 MPa | 160°C (320°F) | Unmatched for thermoplastics |

| Chemical Resistance | Excellent | Withstands most chemicals |

| Wear Resistance | Excellent | Superior to many metals |

| Flame Rating | UL94 V-0 | Self-extinguishing |

| Radiation Resistance | Excellent | Medical sterilization compatible |

3. Material Preparation: The Critical Pre-Processing Phase

Extreme Drying Imperatives:

PEEK is highly hygroscopic with moisture absorption up to 0.5% at equilibrium. Improper drying causes catastrophic defects:

Drying Specifications:

Target Moisture: <0.02% (200 ppm) for critical applications

Drying Temperature: 150°C (302°F) minimum, 180°C (356°F) optimal

Drying Time: 4-6 hours minimum, 8+ hours recommended

Dew Point: -40°C (-40°F) or lower mandatory

Hopper Design: Closed-loop drying with sufficient residence time

Consequences of Insufficient Drying:

Hydrolytic Degradation: Water causes chain scission at high temperatures

Surface Defects: Severe splay, silver streaks, bubbles

Property Loss: Dramatic reduction in mechanical properties

Molecular Weight Drop: Irreversible damage to polymer chains

Processing Issues: Inconsistent flow, poor dimensional control

Material Handling Protocol:

Storage Environment: 23°C ±2°C, <30% relative humidity

Controlled Access: Limit exposure to ambient air

Container Management: Sealed with desiccant when not in use

Time Limits: Maximum 1-2 hours exposure during material changes

Regrind Management Strategy:

Maximum Regrind: 10-15% for critical applications

Thermal History Tracking: Each cycle degrades properties

Separate Processing: Dedicated equipment recommended

Testing Protocol: Regular melt flow and mechanical testing

Colorant Integration:

Limited Options: High processing temperatures restrict choices

Special Masterbatches: PEEK-compatible carriers required

Pre-compounded: Recommended for consistent results

Natural Preference: Many applications use natural color

4. Injection Moulding Machine Requirements

Premium Machine Specifications:

Temperature Capability:

Maximum Required: 400°C (752°F) minimum capability

Temperature Control: ±1°C precision throughout system

Heating Zones: Minimum 5-6 zones with PID control

Heater Bands: High-quality with uniform distribution

Insulation: Comprehensive to minimize heat loss

Screw Design Excellence:

Material: High-grade corrosion-resistant steel

L/D Ratio: 20:1 to 24:1 for proper melting

Compression Ratio: 2.5:1 to 3.0:1

Check Valve: High-performance sliding ring type

Screw Tip: Mixing elements for filled grades

Surface Treatment: Hard chrome or nitrided for wear resistance

Barrel and Nozzle System:

Barrel Material: Bimetallic with corrosion-resistant lining

Capacity: 40-70% of machine rating optimal

Nozzle Type: Open with precise temperature control

Thermocouples: Multiple for accurate temperature mapping

Wear Monitoring: Regular inspection and measurement

Clamping System:

Clamp Force: 4-8 tons per square inch (higher for filled grades)

Platen Parallelism: Critical for precision parts

Tie Bar Strength: Adequate for high injection pressures

Ejection System: Precise, controlled ejection essential

Control System Requirements:

Closed-Loop Control: For all critical parameters

Data Logging: Complete process documentation

Recipe Management: Multiple optimized parameter sets

Integration: With all auxiliary equipment

Auxiliary Equipment:

High-Temperature Dryers: Capable of 180°C operation

Precision Chillers: For mold temperature control

Robotic Systems: For part handling and quality assurance

Environmental Control: For consistent processing conditions

5. Processing Parameters and Optimization

Critical Temperature Parameters:

| Process Zone | Temperature Range | Critical Notes |

|---|---|---|

| Rear Barrel | 340-360°C (644-680°F) | Gentle preheating |

| Middle Zones | 360-380°C (680-716°F) | Main melting phase |

| Front Zone | 380-400°C (716-752°F) | Final homogenization |

| Nozzle | 380-400°C (716-752°F) | Match melt temperature |

| Melt Temperature | 380-400°C (716-752°F) | Critical for crystallization |

| Mold Temperature | 160-200°C (320-392°F) | Essential for properties |

Temperature Management Principles:

Minimum Temperature: Below 360°C risks incomplete melting

Maximum Temperature: Above 420°C causes degradation

Thermal Uniformity: ±5°C maximum variation in melt

Residence Time: Minimize to prevent thermal degradation

Injection Phase Optimization:

Injection Speed:

Fast to very fast injection recommended

Prevents premature freezing in mold

Maintains melt temperature through shear heating

Injection Pressure: 1000-2000 bar (higher for filled grades)

Switchover: 95-98% cavity fill by volume

Back Pressure: 10-20 bar for melt homogenization

Holding/Packing Phase Strategy:

Pressure: 60-80% of injection pressure

Time: Extended (15-30 seconds typical)

Function: Compensates for high shrinkage (1.2-2.0%)

Multi-Stage: Often beneficial for complex parts

Cooling and Crystallization Control:

Cooling Time: 60-120 seconds per mm thickness

Mold Temperature Critical: Controls crystallization rate and degree

Ejection Temperature: Below 200°C to prevent distortion

Annealing: Often required for optimal properties

Special Processing Techniques:

High-Speed Injection: For thin-walled parts

Gas-Assist Moulding: For thick sections

Sequential Gating: For large or complex parts

In-Mould Crystallization: Controlled cooling profiles

6. Tooling Design for PEEK Moulding

Premium Mold Materials:

Cavity/Core: Tool steels H13, S7, or stainless steels

Hardness Requirements: 48-52 HRC minimum

Corrosion Resistance: Essential for consistent performance

Surface Treatments: Nitriding, chrome plating, or PVD coatings

Thermal Conductivity: High conductivity materials preferred

Runner System Design:

Full Round Runners: 8-12mm diameter minimum

Runner Balancing: Critical for multi-cavity molds

Hot Runner Systems: Externally heated with precise control

Gate Types:

Edge Gates: Most common

Direct Sprue: For single-cavity molds

Diaphragm Gates: For cylindrical parts

Hot Tips: For cosmetic surfaces

Temperature Control System:

High-Temperature Capability: Up to 200°C operation

Conformal Cooling: Follows part contours closely

Multiple Circuits: Separate control for different zones

Temperature Uniformity: ±3°C across mold surface

Heated Manifolds: For consistent temperature distribution

Venting System Design:

Vent Depth: 0.010-0.020mm (shallower than many materials)

Vent Width: 6-10mm

Strategic Placement: All end-of-fill areas

Vacuum Venting: Recommended for critical parts

Regular Maintenance: Essential for consistent performance

Ejection System Considerations:

Ejector Pins: Larger diameter to reduce surface pressure

Material Selection: High-temperature resistant steels

Surface Finish: Highly polished to prevent sticking

Ejection Force: Higher due to high stiffness

Sequenced Ejection: For complex geometries

Surface Finish Requirements:

Optical Quality: SPI A-1 for medical and optical parts

Texture Options: Available but affects crystallization

Polish Direction: Consistent to avoid visual defects

Maintenance: Regular polishing to maintain quality

7. Crystallinity Control and Annealing Processes

Understanding PEEK Crystallinity:

Crystalline Content: Typically 30-35% in as-molded parts

Crystallization Temperature: 170-190°C (338-374°F)

Crystal Structure: Orthorhombic unit cells

Property Dependence: Mechanical properties directly related to crystallinity

Factors Affecting Crystallinity:

| Factor | Effect on Crystallinity | Process Control |

|---|---|---|

| Mold Temperature | Higher temp = higher crystallinity | Precise temperature control |

| Cooling Rate | Slower cooling = higher crystallinity | Controlled cooling profiles |

| Nucleating Agents | Increase crystallization rate | Material formulation |

| Molecular Weight | Lower MW = higher crystallinity | Material grade selection |

| Part Thickness | Thicker = higher crystallinity | Design consideration |

Annealing Processes:

Purpose: Increase crystallinity, relieve stresses, improve properties

Temperature: 200-220°C (392-428°F) for 2-4 hours

Atmosphere: Inert gas or vacuum to prevent oxidation

Cooling Rate: Controlled (1-2°C per minute) to room temperature

Benefits: Increased HDT, improved chemical resistance, dimensional stability

Crystallinity Measurement Methods:

DSC (Differential Scanning Calorimetry): Most common method

XRD (X-ray Diffraction): For crystal structure analysis

Density Measurement: Indirect method using density-crystallinity relationship

FTIR Spectroscopy: For chemical structure analysis

Processing for Optimal Crystallinity:

Mold Temperature: Maintain above 160°C for adequate crystallization

Holding Pressure: Sufficient to pack crystals during solidification

Cooling Rate: Controlled to allow proper crystal growth

Post-Mould Annealing: For maximum properties

8. Part Design Guidelines for PEEK

Wall Thickness Principles:

General Range: 1.0-6.0mm

Optimal Thickness: 2.0-3.0mm

Uniformity: Critical (maximum 20% variation)

Minimum Thickness: 0.5mm possible with optimized processing

Thick Sections: Core out to minimize sink marks and reduce stress

Radii and Corner Design:

Internal Radii: Minimum 0.5 times wall thickness

External Radii: Internal radius plus wall thickness

Stress Concentration: Avoid sharp corners completely

Transition Design: Gradual changes (3:1 maximum ratio)

Rib and Boss Design:

Rib Thickness: 40-50% of adjacent wall

Rib Height: Maximum 2.5 times wall thickness

Boss Design: Must be cored and connected with ribs

Draft Angles: 1-2° per side minimum

Fillet Radii: Generous at base connections

Draft Angle Requirements:

Standard Applications: 1-3° per side

High-Aspect Features: Additional draft may be required

Textured Surfaces: Add 1° per 0.025mm texture depth

Medical Implants: Minimum draft for precise fits

Tolerance Considerations:

Standard Tolerances: ±0.1% or ±0.1mm, whichever is greater

Critical Dimensions: ±0.05% achievable with optimization

Thermal Expansion: Account for 4.7 x 10^-5 /°C

Post-Mould Changes: Minimal due to high stiffness

Assembly Feature Design:

Snap-fits: Limited use due to high stiffness

Threads: Molded-in possible with proper design

Press-fits: Careful interference calculations required

Bonding: Designed for specialized adhesives

Mechanical Fastening: Preferred method for most applications

9. Quality Control and Testing Protocols

Material Qualification Testing:

Thermal Analysis:

DSC Analysis: Melting point (343°C), crystallinity percentage

TGA: Thermal stability, decomposition temperature

DMA: Dynamic mechanical properties

HDT/Vicat: Heat deflection and softening points

Mechanical Testing:

Tensile Properties: ASTM D638 at elevated temperatures

Flexural Testing: ASTM D790 for stiffness verification

Impact Resistance: ASTM D256 (Izod/Charpy)

Compressive Strength: ASTM D695 for structural applications

Chemical and Environmental:

Chemical Resistance: Immersion testing per ASTM D543

Hydrolytic Stability: Autoclave testing for medical parts

Radiation Resistance: Gamma sterilization compatibility

Aging Studies: Long-term property retention

Process Control Parameters:

Melt Temperature: Continuous infrared monitoring

Pressure Profiles: Injection and holding phase documentation

Cushion Consistency: ±0.2mm variation maximum

Cycle Time: Statistical process control implementation

Part Validation Testing:

Dimensional Verification: CMM with temperature compensation

Surface Quality: White light interferometry for critical parts

Non-destructive Testing: Ultrasonic or X-ray for internal defects

Functional Testing: Under application conditions

Certification and Documentation:

Material Traceability: Lot tracking from resin to finished part

Process Documentation: Complete parameter records

Quality Certifications: ISO 13485, AS9100, etc.

Customer-Specific Requirements: Often exceed industry standards

10. Industry Applications and Case Studies

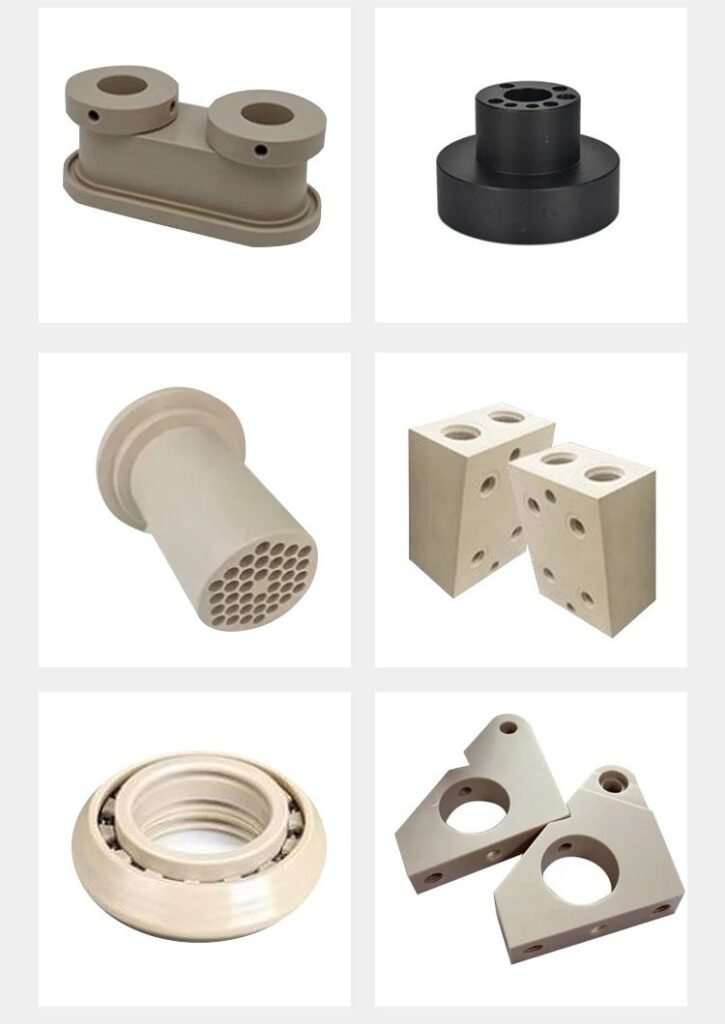

Aerospace and Defense:

Aircraft Components: Brackets, clips, fasteners (25% weight savings vs metal)

Engine Components: Seals, bushings, wear pads

Interior Components: Meeting FAA flammability requirements

Space Applications: Radiation-resistant components

Medical Technology:

Orthopedic Implants: Spinal cages, joint replacements

Dental Instruments: Autoclavable handles and components

Surgical Tools: Lightweight, MRI-compatible instruments

Drug Delivery: Components for infusion pumps

Oil and Gas Industry:

Downhole Components: Seals, bushings, wear rings

Subsea Equipment: Electrical connectors, sensor housings

Valve Components: Seats, seals, guiding elements

Chemical Processing: Pump components, valve parts

Semiconductor Manufacturing:

Wafer Handling: Carriers, end effectors

Process Chamber: Components for plasma environments

Chemical Delivery: Valves, fittings, tubing

Clean Room Equipment: Low particle generation components

Automotive Racing:

Engine Components: Seals, bushings, bearings

Transmission Parts: Wear components, seals

Suspension Components: Bushings, bearings

Electrical Systems: Connectors, sensor housings

Industrial Applications:

Bearings and Bushings: For high-temperature environments

Seals and Gaskets: Chemical and temperature resistance

Electrical Insulation: For high-temperature applications

Wear Components: Superior to many metals

11. Troubleshooting Common PEEK Defects

| Defect | Root Causes | Corrective Actions | Prevention Strategies |

|---|---|---|---|

| Surface Delamination | Moisture contamination, overheating | Verify drying, reduce temperatures | Strict moisture control, temp monitoring |

| Bubbles/Voids | Moisture, insufficient packing | Improve drying, increase pack pressure/time | Proper material handling, process optimization |

| Poor Crystallinity | Low mold temperature, fast cooling | Increase mold temp, adjust cooling rate | Proper mold temperature control |

| Warpage/Distortion | Non-uniform cooling, residual stress | Improve cooling uniformity, annealing | Balanced cooling design, post-mould treatment |

| Short Shots | Low temperature, inadequate pressure | Increase temps 10-20°C, increase pressure | Proper temperature settings, gate optimization |

| Sink Marks | Insufficient packing, thick sections | Increase holding pressure/time, modify design | Uniform wall design, adequate packing |

| Discoloration | Thermal degradation, excessive residence | Lower temperatures, reduce cycle time | Temperature control, optimized cycles |

| Poor Dimensional Stability | Inconsistent processing, improper annealing | Standardize process, implement annealing | Process control, post-mould treatments |

Material-Specific Challenges:

Thermal Degradation: Above 420°C causes permanent damage

Crystallinity Control: Critical for consistent properties

Moisture Sensitivity: Extreme sensitivity requires rigorous control

High Shrinkage: Requires precise mold design compensation

Preventive Quality Measures:

Regular Equipment Calibration: Temperature sensors, pressure transducers

Material Testing: Incoming material qualification

Process Validation: DOE studies for parameter optimization

Continuous Monitoring: Real-time parameter tracking

12. Sustainability and Recycling Considerations

Recycling Challenges and Opportunities:

Mechanical Recycling:

Property Retention: Good with limited thermal history

Maximum Regrind: 10-15% for critical applications

Sorting Requirements: Must be separated from other polymers

Applications: Lower-grade applications possible

Chemical Recycling:

Depolymerization: Back to monomer possible but complex

Solvent Recovery: For certain applications

Pyrolysis: To chemical feedstocks

Current Status: Developing but not commercial scale

Energy Recovery:

Calorific Value: 32-34 MJ/kg (higher than many polymers)

Waste-to-Energy: Efficient option for contaminated material

Environmental Considerations: Halogen-free combustion

Sustainable Manufacturing Initiatives:

Energy Efficiency: Optimized processing reduces energy consumption

Material Optimization: Minimal waste through design

Extended Product Life: Long service life reduces environmental impact

Lightweighting: Replacing metals reduces energy in use phase

Industry Programs and Certifications:

Environmental Management: ISO 14001 implementation

Material Stewardship: Responsible sourcing and use

Life Cycle Assessment: Comprehensive environmental analysis

Industry Collaboration: Across value chain for sustainability

13. Future Trends and Innovations

Material Science Advancements:

Enhanced Grades: Higher temperature resistance, improved flow

Bio-based PEEK: From renewable monomers (developing)

Nanocomposites: Enhanced properties at lower loadings

Smart PEEK: Functional additives for specific properties

Processing Technology Evolution:

Industry 4.0 Integration: AI-driven process optimization

Additive Manufacturing: 3D printing with PEEK filaments

Micro-moulding: For medical micro-devices

Hybrid Processes: Combining different manufacturing methods

Application Expansion:

Additive Manufacturing: Custom medical implants, complex aerospace parts

Electric Vehicles: High-temperature electrical components

Renewable Energy: Components for extreme environments

Advanced Medical: Bioactive implants, drug delivery systems

Sustainability Innovations:

Improved Recycling: Better separation and recovery technologies

Circular Economy: Closed-loop material systems

Carbon Footprint Reduction: Throughout product lifecycle

Sustainable Formulations: Reduced environmental impact

Market and Regulatory Trends:

Cost Reduction: Through improved manufacturing efficiency

Standardization: Global standards for high-performance polymers

Regulatory Compliance: Evolving requirements for medical and aerospace

Supply Chain Optimization: For consistent quality and availability

14. Conclusion: Mastering High-Performance Polymer Processing

PEEK injection moulding represents the pinnacle of polymer processing technology, demanding:

Material Mastery: Deep understanding of PEEK’s unique characteristics

Process Excellence: Precise control of all parameters

Equipment Capability: Specialized machinery and tooling

Quality Commitment: Uncompromising standards for critical applications

Technical Expertise: Continuous learning and improvement

The future of PEEK processing lies in expanding its capabilities while improving accessibility and sustainability. Through material innovations, processing advancements, and application development, PEEK will continue to enable solutions for the world’s most challenging engineering problems.

For manufacturers, PEEK offers opportunities to participate in high-value markets with demanding requirements. The barriers to entry are significant – requiring investment in specialized equipment, technical expertise, and quality systems. However, the rewards – in terms of market positioning, technical capability, and customer relationships – justify the investment.

As technology advances and new applications emerge, those who have mastered PEEK processing will be best positioned to lead in advanced manufacturing. The journey is challenging, but the destination – producing components that operate reliably in extreme environments and enable technological advancement – is worth the effort.