Introduction

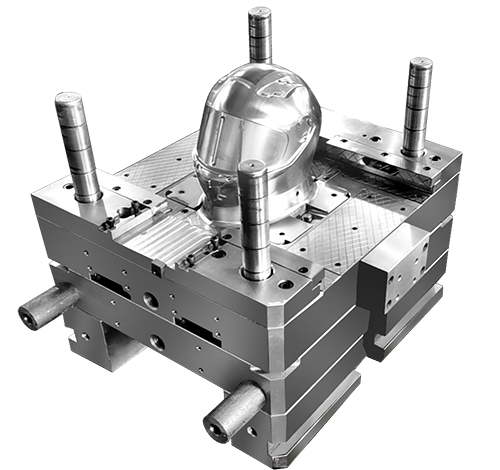

In the realm of personal protective equipment (PPE), a helmet is a critical lifeline. Its integrity begins not on the production line, but within the precision of its mold. Our advanced injection molds for plastic helmets are engineered to be the cornerstone of your manufacturing process, delivering unmatched consistency, superior impact strength, and operational efficiency. We partner with you to create the foundation for safety you can trust.

1. Core Engineering Advantages

Our molds are built on a foundation of innovative engineering, designed to maximize performance, durability, and return on investment.

Core Advantages Comparison Table

| Advantage | Conventional Mold | Our Advanced Helmet Mold | Your Benefit |

|---|---|---|---|

| Structural Integrity | Basic flow leading to potential weak points. | CAE-Optimized Melt Flow & Gating | Superior, consistent impact resistance across the entire helmet shell, crucial for safety certification. |

| Production Uptime | Standard materials leading to wear and maintenance. | High-Grade Stainless Steel (420SS/NAK80) on critical surfaces. | Extended mold life, reduced polishing frequency, and consistent part quality over millions of cycles. |

| Cycle Time & Efficiency | Straight-drilled cooling channels. | Conformal Cooling Channels following the helmet’s complex geometry. | Up to 30% faster cycle times, reduced energy consumption, and elimination of warpage. |

| Automation Readiness | Manual part handling. | Integrated Robotic Interface & Automatic Undercore | Fully automated, lights-out production, reduced labor costs, and elimination of handling damage. |

2. In-Depth Technical Specifications

Every component is specified to meet the rigorous demands of high-volume, high-quality safety helmet production.

Technical Specifications Table

| Category | Specification | Impact on Final Product |

|---|---|---|

| Mold Base & Plates | Standard 1050/1715 Steel; Precision ground and hardened. | Provides absolute rigidity and stability, preventing deflection under high injection pressure. |

| Cavity & Core | Premium Stainless Steel (420SS); High-Polish (SPI A1) or textured finish. | Guarantees a flawless Class-A surface finish, free of flow lines or blemishes, right from the press. |

| Gating System | Hot Runner System with valve-gate sequencing. | Elimates material waste (no runner), ensures balanced filling, and allows for a clean gate separation. |

| Ejection System | Ejector Sleeves & Blades with guided ejector plates and proximity sensors. | Ensures gentle, yet positive, ejection from the complex undercuts without stressing or marking the helmet. |

| Cooling System | 3D Conformal Cooling with baffles and bubblers in deep core areas. | Enables uniform heat extraction, critical for achieving consistent molecular orientation and impact strength. |

| Venting | Precision micro-vents at parting lines and ejector pins. | Prevents gas traps (burn marks) and vacuum issues, ensuring a defect-free shell and stable demolding. |

3. Product Features & Tangible Benefits

Our design philosophy translates technical features into direct benefits for your production and product quality.

- Feature: CAE-Optimized Filling & Packing

- Benefit: Using advanced Computer-Aided Engineering (CAE), we simulate the flow of plastic to ensure perfect filling balance and optimal packing pressure. This process is critical for eliminating weak spots and internal stresses, resulting in a helmet shell with homogeneous impact strength that reliably passes stringent safety tests like ANSI/ISEA Z89.1 or EN 397.

- Feature: Automated Undercore & Robotic Extraction

- Benefit: The helmet’s inner geometry creates significant undercuts. Our mold incorporates an automated undercore mechanism that retracts before ejection, allowing for a damage-free demolding process. Coupled with standardized interfaces for robotic arms, this enables a fully automated production cell, maximizing output and ensuring gentle handling of the finished product.

- Feature: Superior Surface Finish Options

- Benefit: The cavity is machined and finished to the highest standards, capable of achieving a high-gloss polish (SPI A1) for a premium look or a variety of textures (grain, matte). This ensures your helmets have an exceptional aesthetic appeal straight from the mold, reducing the need for secondary operations and enhancing brand perception.

4. Our Service & Partnership Commitment

We are more than a supplier; we are your technical partner in manufacturing excellence.

- Comprehensive DFM (Design for Manufacturability) Report: Before any steel is cut, we provide a detailed analysis of your helmet design, suggesting optimizations for moldability, cost, and performance to de-risk your project.

- Prototyping & Validation Support: We support the creation of initial samples for safety testing and marketing, ensuring the final product meets all requirements before mass production.

- Global Technical Support & Maintenance: Our commitment doesn’t end at delivery. We offer lifelong technical support, spare parts, and maintenance services to ensure your mold operates at peak performance for its entire lifecycle.

Conclusion: The Foundation of Safety Starts Here

The integrity of every helmet you produce is fundamentally linked to the quality of its mold. By investing in our precision-engineered injection mold solution, you are not just purchasing a tool; you are securing a reliable, efficient, and high-quality foundation for your most critical PPE products.

Contact us today to schedule a consultation and receive a free, no-obligation DFM analysis of your helmet design. Let’s build a safer world, together.