Your End-to-End Manufacturing Partner: From Vision to Volume

In today’s fast-paced market, the bridge between a groundbreaking idea and a flawless, high-volume product is built on expertise, precision, and seamless integration. Our company is that bridge. We offer a complete, in-house solution that navigates the entire product development journey, eliminating the traditional friction, miscommunication, and delays of using multiple vendors. By mastering every critical phase under one roof, we ensure unmatched quality control, accelerated timelines, and optimal cost-efficiency. Our process is built on four foundational pillars:

Product Design & Engineering: Where your concept is engineered for reality.

Rapid Prototyping: Where digital designs become tangible, testable models.

Precision Mold Fabrication: Where the heart of mass production is crafted.

High-Volume Injection Molding: Where your product is born at scale.

Module 1: Product Design & Engineering – Architecting Success from the First Sketch

The journey to a superior product begins with a foundation of exceptional design. Our engineering team doesn’t just create shapes; we engineer solutions that are innovative, manufacturable, and market-ready. We employ a Design for Manufacturing (DFM) and Design for Assembly (DFA) philosophy from day one, ensuring that aesthetic vision never compromises production efficiency or cost-effectiveness.

Concept Development & Feasibility: We collaborate with you to refine your idea, conducting user-centric research and translating requirements into actionable design specifications. Our sketches and initial 3D models focus on form, function, and user experience.

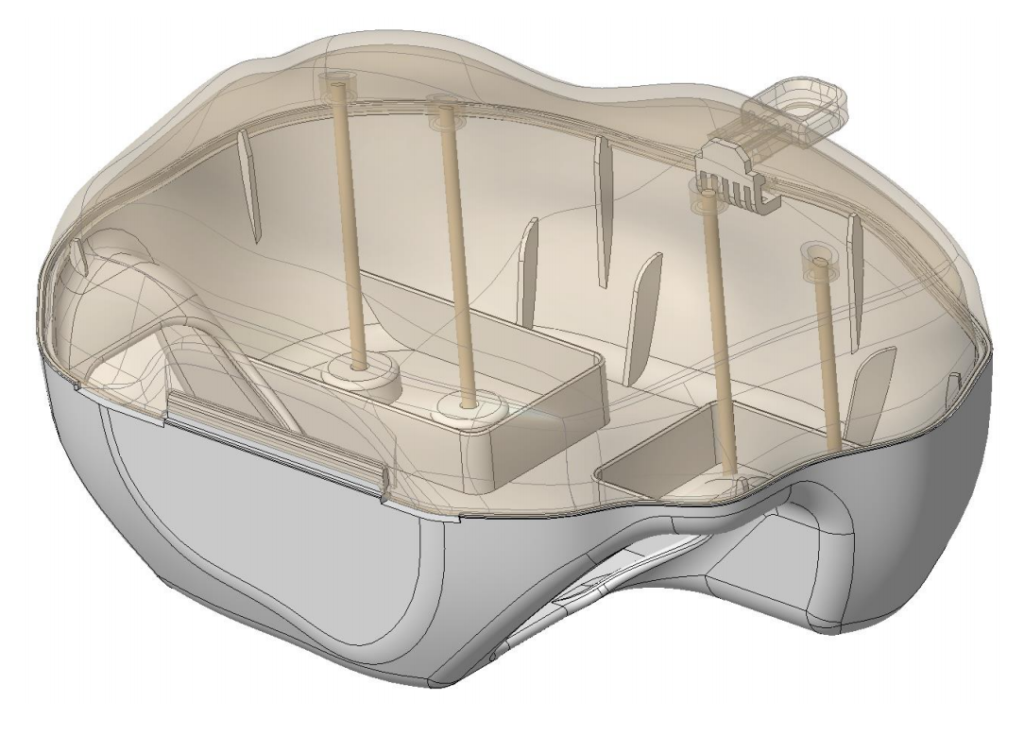

Advanced 3D CAD & Simulation: Using industry-leading software, we build a precise digital twin of your product. This model undergoes rigorous virtual testing:

Finite Element Analysis (FEA) for structural integrity.

Computational Fluid Dynamics (CFD) for thermal or fluid management.

Plastic Flow Simulation to predict injection molding behavior, optimizing wall thickness and gate locations to prevent defects.

Material Selection Guidance: We advise on the optimal polymer based on your product’s needs for strength, flexibility, chemical resistance, color, and regulatory compliance (e.g., FDA, UL).

| Service Aspect | Tools & Methods | Direct Benefit to You |

|---|---|---|

| Concept & 3D Modeling | SolidWorks, CREO, Autodesk Inventor | Clear visualization and early buy-in for your idea. |

| Engineering Analysis (FEA/CFD) | ANSYS, SolidWorks Simulation | Reduced physical testing costs; ensured product reliability. |

| Molding Simulation | Moldflow, Moldex3D | Prevention of costly mold rework; perfect part design. |

| DFM/DFA Report | Proprietary checklists & review process | Guaranteed design optimized for cost-effective, high-quality mass production. |

Module 2: Rapid Prototyping – Bridging the Digital and Physical Worlds

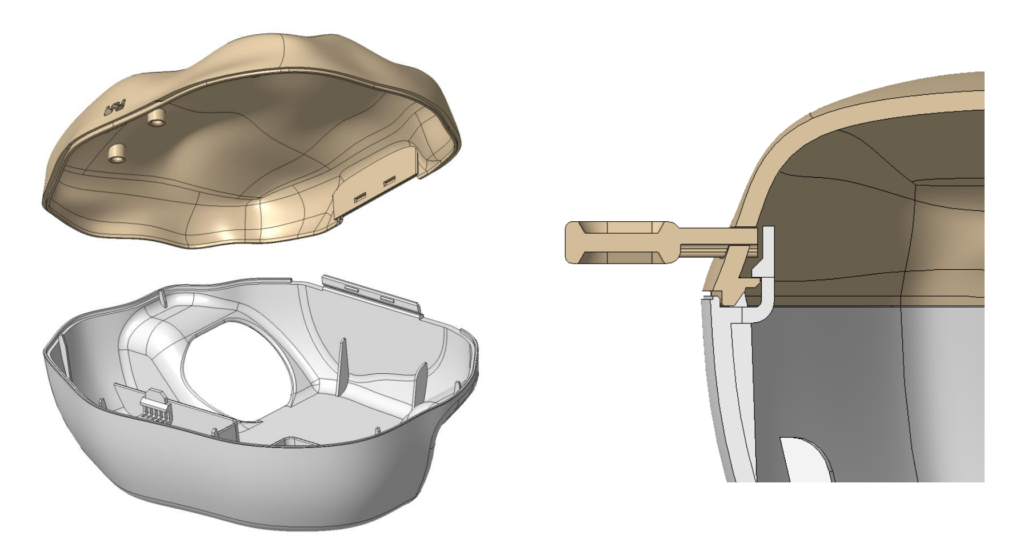

Before committing to expensive tooling, it is essential to validate your design in the real world. Our rapid prototyping services provide the critical link between digital models and physical verification, enabling functional testing, user feedback, and design refinement.

Multi-Technology Approach: We employ the right technology for your prototype’s purpose:

SLA (Stereolithography): For high-detail, smooth-finish concept models and visual aids.

SLS (Selective Laser Sintering): For durable, functional components that can handle stress and assembly.

CNC Machining: For precision prototypes from real production-grade plastics or metals, offering the most accurate material properties.

Vacuum Casting (Urethane Casting): For small batches of prototype parts that closely mimic the look and feel of final injection-molded parts.

Functional Testing & Iteration: Prototypes are used for fit checks, assembly validation, ergonomic testing, and even small-scale beta launches. This agile process allows for rapid design iterations, converging on the perfect final design before mold fabrication begins.

See how a digital file transforms into a functional prototype in seconds:

Module 3: Precision Mold Fabrication – Engineering the Heart of Production

The mold is the most critical tool in injection molding; its quality defines the quality, consistency, and efficiency of your entire production run. Our mold shop is where artistry meets aerospace-level precision.

Design & Steel Selection: Our mold designers, working hand-in-hand with our product engineers, create robust mold designs. We select the appropriate mold steel (e.g., P20, H13, Stainless) based on production volume, material abrasiveness, and required part finish.

State-of-the-Art Machining: We utilize advanced CNC milling, EDM (Electrical Discharge Machining), and deep-hole drilling to create mold cavities and cores with micron-level accuracy.

Surface Finishing & Texturing: Our skilled polishers achieve mirror finishes or apply custom textures (e.g., leather, matte, geometric patterns) to give your product its unique tactile and visual identity.

Mold Validation & Sampling: Upon completion, every mold is rigorously tested on our injection presses. We produce initial T1 samples for your approval, ensuring the molded part meets all specifications before full production commences.

| Mold Type | Best For | Lead Time | Life Expectancy | |

|---|---|---|---|---|

| Prototype/Soft Mold | Aluminum | Low-volume runs (50-5,000 parts) | 4-8 weeks | 10,000 – 50,000 shots |

| Production Mold | Hardened Steel | High-volume runs (100k+ parts) | 8-16 weeks | 1,000,000+ shots |

| Multi-Cavity/Multi-Shot | Premium Steels | Complex parts, high output | 12-20+ weeks | >1,000,000 shots |

Module 4: Injection Molding Production – Excellence at Scale

This is where your vision becomes a tangible, market-ready reality. Our injection molding floor is equipped with modern, computerized presses ranging from small tonnage for精密 parts to large machines for substantial components.

Process Optimization: Our expert technicians fine-tune critical parameters—temperature, pressure, injection speed, cooling time—to achieve optimal part quality and cycle time.

Full Automation & Quality Control: We integrate robotics for part removal, sprue picking, and assembly to ensure consistency and reduce labor costs. Our quality lab performs in-process inspections using CMM (Coordinate Measuring Machine), vision systems, and mechanical testers against your approved control plan.

Secondary Operations & Assembly: We provide a complete post-molding suite, including:

Ultrasonic welding

Heat staking

Precision painting and pad printing

Threaded inserts

Full product assembly, packaging, and kitting

The Integrated Advantage: Why Our Full-Service Model Wins

Choosing separate vendors for design, prototyping, tooling, and production creates communication gaps, finger-pointing, and costly delays. Our integrated model offers:

Single-Point Accountability: One team, one responsibility for your project’s success.

Seamless Knowledge Transfer: Lessons from prototyping directly inform mold design; molding insights are fed back to our designers for future projects.

Drastically Reduced Time-to-Market: Concurrent engineering and eliminated vendor handoffs shave weeks or months off your schedule.

Total Cost Optimization: DFM from the start and in-house control prevent expensive rework and change orders.

Your Vision, Manufactured Perfectly – Let’s Begin.

Are you ready to streamline your path from concept to customer? Partner with us to leverage a seamless, expert-driven process that guarantees quality, speed, and value.

Take the first step toward flawless production.

Contact our engineering team today for a confidential design consultation and quote. Let us show you how our end-to-end expertise can bring your product to life, efficiently and brilliantly.