PA6/PA66+GF injection molding

- Home

- / Material /

- PA6/PA66+GF injection molding

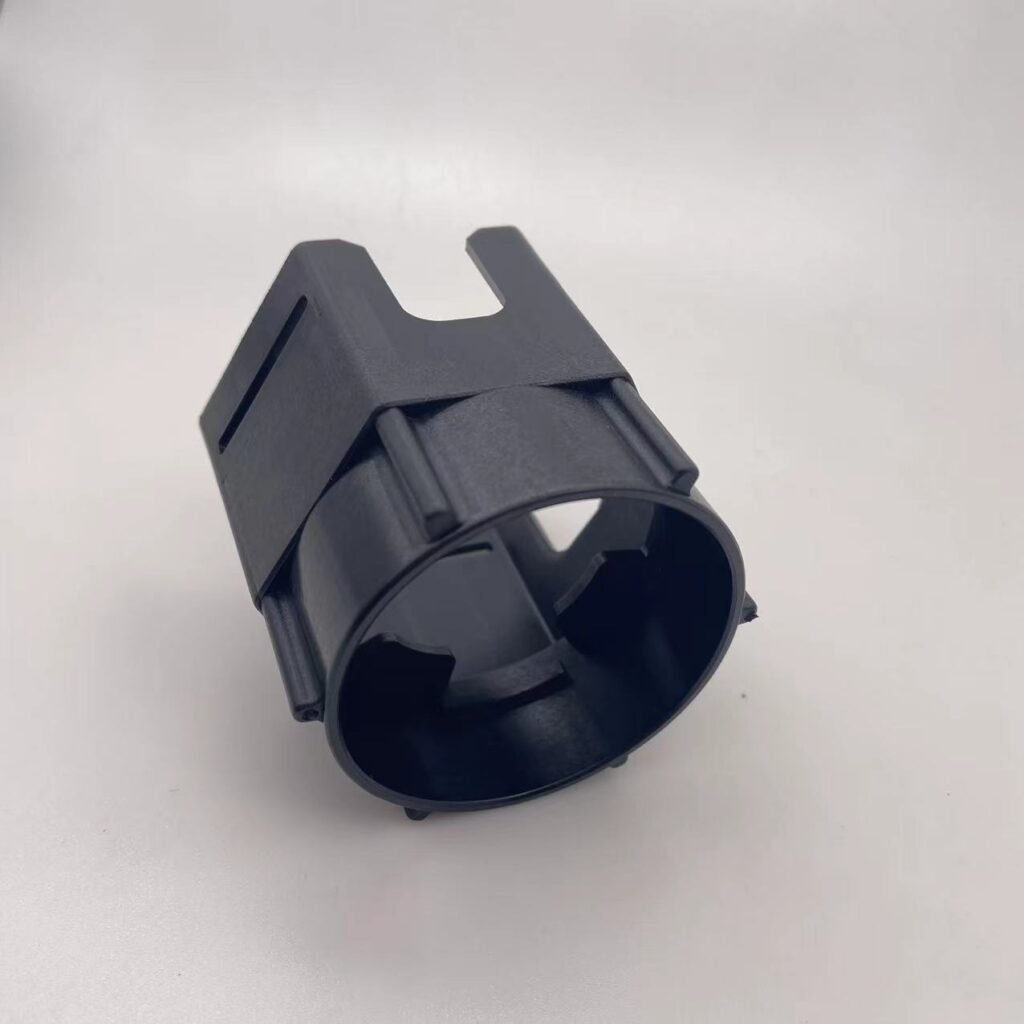

Glass-Fiber Reinforced Nylon (GF-PA) Injection Moulding: The High-Performance Composite Solution

1. Introduction: Reinforcing Excellence

The incorporation of glass fibers into polyamide matrices represents one of the most significant advancements in engineering plastics technology. Glass-fiber reinforced nylons (GF-PA) combine the inherent benefits of polyamide—excellent mechanical properties, chemical resistance, and thermal stability—with the enhanced stiffness, dimensional stability, and heat resistance provided by fiber reinforcement. This synergistic combination creates materials capable of replacing metals in demanding applications while offering weight reduction, design freedom, and corrosion resistance.

From automotive underhood components to industrial machinery and electrical enclosures, GF-PA has become the material of choice where strength, stiffness, and dimensional precision are paramount. This comprehensive guide explores the specialized world of glass-fiber reinforced nylon injection moulding, addressing the unique challenges and opportunities presented by these advanced composite materials.

2. Material Science: The Reinforcement Mechanism

Reinforcement Fundamentals:

Glass-fiber reinforced nylons typically contain 10% to 50% glass fiber by weight, with 30% and 50% being the most common commercial grades. The reinforcement mechanism operates through several key principles:

Load Transfer Mechanism:

Fiber-Matrix Adhesion: Silane coupling agents chemically bond fibers to the nylon matrix

Stress Distribution: Fibers carry load more efficiently than the polymer matrix

Crack Propagation Inhibition: Fibers impede and deflect crack growth

Fiber Characteristics:

Type: E-glass most common; S-glass for higher performance

Length: Typically 0.2-0.4mm after compounding (original 3-6mm)

Diameter: 10-20 microns

Aspect Ratio: Critical for reinforcement efficiency (optimal: 20:1 to 40:1)

Property Enhancement Compared to Unreinforced PA:

| Property | Improvement vs. Unfilled PA | Typical Values (30% GF-PA6) |

|---|---|---|

| Tensile Strength | 2-3x increase | 160-200 MPa |

| Flexural Modulus | 3-5x increase | 8-10 GPa |

| Heat Deflection Temp | 100-150°C increase | 210-220°C @ 1.82 MPa |

| Creep Resistance | 10-100x improvement | Minimal deformation under load |

| Dimensional Stability | Significant improvement | 0.2-0.4% moisture expansion |

Fiber Orientation Effects:

Flow Direction: Fibers align with melt flow, creating anisotropic properties

Property Differential: 2-3x higher strength in flow direction vs. transverse

Design Consideration: Part design must account for anisotropic behavior

3. Material Preparation and Handling

Enhanced Drying Requirements:

Glass-filled nylons present more demanding drying requirements due to increased surface area and potential moisture entrapment:

Drying Specifications:

Temperature: 100-110°C for GF-PA6/66 (higher than unfilled grades)

Time: 6-8 hours minimum (extended for higher fiber content)

Target Moisture: <0.05% (500 ppm) for optimal processing

Dew Point: -40°C or lower mandatory

Consequences of Insufficient Drying: Severe splay, mechanical property loss, poor surface finish

Material Handling Challenges:

Abrasiveness: Glass fibers accelerate screw and barrel wear

Segregation: Fibers can separate from pellets during handling

Contamination: Special care needed to prevent contamination of unfilled materials

Static Electricity: More prone to static buildup

Regrind Management:

Maximum Regrind: 15-20% recommended (lower than unfilled PA)

Property Degradation: Fiber length reduction with each processing cycle

Separate Processing: Dedicate equipment for GF grades when possible

Testing Protocol: Regular mechanical testing to monitor property retention

4. Machine Configuration for GF-PA Processing

Specialized Equipment Requirements:

Barrel and Screw Modifications:

Screw Design:

Compression ratio: 2.0:1 to 2.5:1 (lower than unfilled PA)

L/D ratio: 18:1 to 20:1

Wear-resistant coatings: Tungsten carbide, bimetallic linings

Shallow flight depths: To minimize fiber breakage

Check Valve: Sliding ring type with hardened surfaces

Nozzle: Open nozzle with wear-resistant tip

Wear Protection:

Bimetallic Barrels: Hardened inner surfaces (Rc 58+)

Hardened Screws: Surface hardness Rc 60-65

Special Liners: For extreme abrasion resistance

Regular Inspection: Monitor screw and barrel wear

Clamping System:

Higher Tonnage: 4-7 tons per square inch (increased for higher viscosity)

Platen Parallelism: Critical for consistent fiber orientation

Ejection Force: Increased due to higher stiffness and shrinkage

5. Processing Parameters and Optimization

Temperature Settings for GF-PA:

| Parameter | 15% GF-PA66 | 30% GF-PA66 | 50% GF-PA66 |

|---|---|---|---|

| Rear Zone | 270-290°C | 280-300°C | 290-310°C |

| Middle Zone | 285-300°C | 295-310°C | 305-320°C |

| Front Zone | 295-310°C | 305-320°C | 315-330°C |

| Nozzle | 295-310°C | 305-320°C | 315-330°C |

| Melt Temp | 285-305°C | 295-315°C | 305-325°C |

| Mould Temp | 80-100°C | 90-110°C | 100-120°C |

Injection Phase Strategy:

Injection Speed:

Moderate to fast (optimize for fiber orientation)

Too slow: Poor fiber distribution

Too fast: Excessive fiber breakage and jetting

Injection Pressure: 1000-1600 bar (higher than unfilled grades)

Back Pressure: 5-15 bar (minimize fiber breakage)

Holding/Packing Phase:

Pressure: 50-70% of injection pressure

Time: Critical for dimensional stability

Function: Compensates for reduced shrinkage

Cooling Considerations:

Extended Cooling: GF-PA requires longer cooling than unfilled grades

Mould Temperature: Higher temperatures improve surface finish

Ejection Temperature: 100-120°C range

Fiber Length Preservation Strategy:

Moderate Screw Speed: 50-100 RPM optimal

Minimize Back Pressure: Only enough for melt homogeneity

Optimize Temperature: Avoid excessive heating zones

Proper Gating: Avoid restrictive gates that break fibers

6. Tooling Design for Glass-Filled Nylon

Enhanced Tooling Requirements:

Mould Material and Hardness:

Cavity/Core: Premium hardened steels (H13, S7, 420SS)

Hardness: 48-55 HRC minimum

Surface Treatments: Nitriding, chrome plating, or PVD coatings

Regular Maintenance: More frequent polishing and inspection

Runner and Gate Design:

Runner Size: Larger than unfilled grades (8-12mm diameter)

Full Round Runners: Essential for fiber preservation

Gate Design:

Size: 30-50% larger than for unfilled materials

Type: Tab gates preferred to reduce jetting

Location: Strategic to control fiber orientation

Hot Runners: Externally heated with temperature control ±3°C

Wear-Resistant Features:

Hardened Ejector Pins: Reduced galling and wear

Guide Bushings: Wear-resistant materials

Corrosion Protection: Essential for moisture resistance

Easy Maintenance: Design for frequent cleaning

Venting System:

Additional Vents: More vents than unfilled materials

Vent Depth: 0.020-0.035mm (slightly deeper)

Strategic Placement: At weld lines and end-of-fill areas

7. Part Design Considerations for GF-PA

Key Design Modifications:

Wall Thickness Optimization:

Uniformity: More critical than with unfilled PA (max 15% variation)

Minimum Thickness: 1.0-1.5mm (thicker than unfilled PA)

Thick Sections: Avoid when possible; core out if necessary

Radii and Corner Design:

Generous Radii: Minimum 1.0mm internal radius

Avoid Sharp Corners: Stress concentration exacerbated by fibers

Transition Design: Gradual changes in cross-section

Rib and Boss Design:

Rib Thickness: 40-50% of adjacent wall (thinner than unfilled PA)

Rib Height: Limited to 2.5x wall thickness

Boss Design: Must be well-supported with ribs

Draft Angles: Increased to 2-3° per side

Fiber Orientation Management:

Gate Location: Determines primary fiber orientation

Flow Path Design: Consider anisotropic properties in load-bearing areas

Weld Line Positioning: Place in low-stress areas

Shrinkage Considerations:

Differential Shrinkage: Flow direction: 0.2-0.4%; Transverse: 0.8-1.2%

Mould Design Compensation: Account for anisotropic shrinkage

Post-Mould Changes: Minimal compared to unfilled PA

8. Anisotropy Management and Warpage Control

Understanding Anisotropic Behavior:

GF-PA exhibits significantly different properties in flow direction versus transverse direction:

Property Anisotropy:

Tensile Strength: 2-3x higher in flow direction

Modulus: 2-2.5x higher in flow direction

Thermal Expansion: 3-4x higher in transverse direction

Shrinkage: 2-3x higher in transverse direction

Warpage Control Strategies:

Design-Level Solutions:

Symmetrical Rib Patterns: Balance fiber orientation

Uniform Wall Thickness: Minimize differential cooling

Strategic Gating: Control flow patterns and fiber alignment

Corner Reinforcement: Additional material at high-stress corners

Process-Level Solutions:

Optimized Mould Temperature: Higher temps reduce orientation

Balanced Filling: Multi-point gating for complex parts

Holding Pressure Optimization: Reduces differential shrinkage

Post-Mould Conditioning: Controlled cooling fixtures

Tooling Solutions:

Conformal Cooling: Uniform temperature distribution

Mould Surface Textures: Can help mask warpage effects

Adjustable Inserts: For fine-tuning dimensions

9. Surface Finish and Appearance Challenges

Common Surface Issues:

Fiber Read-Through (Fiber Bloom):

Appearance: Fibers visible on surface

Causes:

Improper processing conditions

Inadequate mould temperature

Excessive shear

Solutions:

Increase mould temperature (100-120°C)

Optimize injection speed

Use surface finish additives

Weld Line Weakness and Visibility:

Challenge: More pronounced than with unfilled PA

Strength Reduction: Up to 50-70% at weld lines

Improvement Strategies:

Increased melt and mould temperatures

Higher injection speed at weld areas

Strategic venting at weld locations

Surface Finish Options:

High-Gloss Finishes: Challenging but possible with optimal processing

Textured Surfaces: Effective at hiding fiber read-through

Painted Surfaces: Require proper surface preparation

Plated Surfaces: Special grades available for plating

Cosmetic Enhancement Techniques:

Mould Surface Treatments: Polished surfaces reduce fiber visibility

Processing Adjustments: Slower fill speeds for better surface

Additives: Surface modifiers and special colorants

Post-Mould Operations: Sanding, painting, coating

10. Secondary Operations and Assembly

Machining Considerations:

Tool Wear: Accelerated due to abrasive fibers

Tool Selection: Carbide or diamond-coated tools recommended

Cutting Parameters: Higher speeds, lower feeds

Cooling: Essential to prevent melting and tool damage

Joining Methods:

Mechanical Fastening:

Self-Tapping Screws: Successful with proper boss design

Inserts: Ultrasonic, thermal, or molded-in

Design Considerations: Account for higher stiffness and creep resistance

Welding and Bonding:

Ultrasonic Welding: Challenging but possible with energy directors

Vibration Welding: Most reliable method for GF-PA

Adhesive Bonding: Surface preparation critical (abrasion, primers)

Solvent Bonding: Not generally recommended

Post-Mould Treatments:

Annealing: Reduces molded-in stresses

Humidity Conditioning: Less critical than unfilled PA

Surface Coating: For improved appearance or functionality

11. Quality Control and Testing

Specialized Testing Requirements:

Fiber Characterization:

Fiber Length Distribution: Ashing method or image analysis

Fiber Orientation: Micro-CT scanning or microscopy

Fiber-Matrix Adhesion: Single fiber pull-out tests

Mechanical Testing Considerations:

Anisotropic Testing: Test specimens in multiple orientations

Notch Sensitivity: GF-PA is more notch-sensitive than unfilled PA

Fatigue Testing: Essential for dynamic applications

Non-Destructive Testing:

Ultrasonic Inspection: For internal defects

X-ray Imaging: For fiber orientation mapping

Thermal Imaging: For stress pattern analysis

Process Control Parameters:

Consistent Cushion: Critical for dimensional stability

Melt Temperature Monitoring: More critical than unfilled grades

Regular Screw Inspection: For wear monitoring

12. Advanced Applications and Case Studies

Automotive Structural Components:

Intake Manifolds: 30-35% GF-PA6 or PA66

Engine Covers: 30% GF-PA for heat resistance

Structural Brackets: Replacing metal with 50% GF-PA

Benefits: Weight reduction up to 50% vs. aluminum

Aerospace and Defense:

Drone Frames: High stiffness-to-weight ratio

Equipment Housings: EMI shielding capabilities

Structural Components: 50% GF-PA for maximum performance

Industrial Machinery:

Gears and Bearings: 30% GF-PA with internal lubrication

Pump Housings: Chemical resistance with structural integrity

Conveyor Components: Wear resistance and strength

Electrical and Electronics:

Connector Housings: 15-30% GF-PA for dimensional stability

Circuit Breakers: Arc resistance and thermal properties

Enclosures: Flame retardant GF-PA grades

Sports and Recreation:

Bicycle Components: 30% GF-PA for strength and weight savings

Professional Equipment: Durability and performance

13. Troubleshooting GF-PA Specific Issues

| Problem | Root Causes | Corrective Actions |

|---|---|---|

| Excessive Fiber Breakage | High screw speed, excessive back pressure, restrictive flow | Reduce RPM to 50-100, minimize back pressure, enlarge gates/runners |

| Poor Surface Finish | Low mould temperature, fast injection, improper drying | Increase mould temp to 100-120°C, moderate injection speed, verify drying |

| Weld Line Weakness | Low temperatures, poor venting, improper gate design | Increase melt/mould temps, add vents at weld lines, relocate gates |

| Short Shots | High viscosity, inadequate pressure, restricted flow | Increase temperatures 10-20°C, increase pressure, enlarge flow channels |

| Warpage | Anisotropic shrinkage, non-uniform cooling, improper gate location | Optimize gate placement, improve cooling uniformity, consider sequential gating |

| Splay Marks | Moisture contamination, overheating, excessive shear | Verify drying (<0.05%), reduce melt temperature, moderate injection speed |

| Dimensional Variation | Inconsistent processing, worn tooling, inadequate packing | Standardize process, maintain tooling, optimize holding phase |

Preventive Maintenance Schedule:

Daily: Check and clean vents

Weekly: Inspect screw and barrel for wear

Monthly: Verify temperature calibration

Quarterly: Complete machine maintenance

14. Future Trends and Innovations

Advanced Fiber Technologies:

Long Fiber Reinforcements: Pellets with fibers up to 10mm length

Continuous Fiber Reinforcement: In-mould placement technologies

Hybrid Reinforcements: Glass + carbon fiber combinations

Nanofiber Reinforcements: Enhanced properties at lower loadings

Process Innovations:

In-Mould Sensor Integration: Real-time monitoring of fiber orientation

Adaptive Process Control: Automatic adjustment for consistent properties

Multi-Material Moulding: Combining GF-PA with other materials

Additive Manufacturing: 3D printing with fiber-reinforced filaments

Sustainability Initiatives:

Recycled Glass Fibers: From post-industrial or post-consumer sources

Bio-based Nylon Matrices: Renewable PA11/PA1010 with glass fibers

Improved Recyclability: Designed for mechanical or chemical recycling

Lightweighting: Further weight reduction for energy savings

Smart Materials Development:

Self-Healing Composites: Microcapsule technology for damage repair

Conductive Composites: For EMI shielding and static dissipation

Thermally Conductive Grades: For heat management applications

15. Conclusion: Mastering High-Performance Composites

Glass-fiber reinforced nylon injection moulding represents the convergence of material science, precision engineering, and practical processing expertise. Success with these advanced composites requires:

Respect for Material Characteristics: Understanding fiber-matrix interactions

Specialized Equipment: Properly configured for abrasive materials

Precise Process Control: Consistency is paramount for quality

Design for Manufacturing: Accounting for anisotropic behavior

Continuous Learning: Staying current with material and process innovations

The future of GF-PA lies in continued performance enhancement, improved sustainability, and expanded applications in demanding environments. As industries increasingly seek lightweight, durable alternatives to metals, glass-fiber reinforced nylons will play an ever-more critical role in product design and manufacturing.

For manufacturers venturing into or expanding their GF-PA capabilities, the investment in proper equipment, training, and process development yields significant returns in product performance, customer satisfaction, and competitive advantage. The challenges are substantial, but the rewards—in terms of product capabilities and market opportunities—are equally significant.