PP injection molding

- Home

- / Material /

- PP injection molding

A Comprehensive Guide to Polypropylene (PP) Injection Moulding: Process, Parameters, and Applications

1. Introduction: The Ubiquitous Polymer

Polypropylene (PP) stands as one of the most versatile and widely produced thermoplastic polymers in the world. Its unique combination of properties—excellent chemical resistance, low density, good fatigue resistance, and cost-effectiveness—has made it the material of choice for a staggering array of applications. From automotive interiors and battery casings to food packaging, medical devices, and consumer products, PP is integral to modern manufacturing. The primary enabler of this ubiquity is the process of injection moulding, a high-efficiency method capable of producing complex, high-tolerance parts at massive scales. This article provides a detailed, 2000-word exploration of PP injection moulding, covering material science, the process mechanics, critical parameters, design considerations, common defects, and future trends.

2. Material Science: Understanding Polypropylene

Understanding the material is the first step to mastering its processing. PP is a semi-crystalline thermoplastic polymer synthesized from propylene monomers.

Types and Structure: The most common commercial type is isotactic polypropylene, where methyl groups are aligned on the same side of the carbon backbone. This regular structure allows for a high degree of crystallinity (typically 40-60%), which directly influences its mechanical properties, including stiffness, strength, and thermal resistance.

Key Properties:

Low Density (~0.905 g/cm³): Makes it one of the lightest commodity plastics, offering significant weight-saving advantages.

Excellent Chemical Resistance: Inert to a wide range of bases, acids, detergents, and oils.

Good Fatigue Resistance: Enables the famous “living hinge” feature, allowing parts to be flexed repeatedly without failure.

Good Electrical Insulator.

Biocompatibility: Certain grades are approved for food contact and medical applications.

Modifications and Additives: Homopolymer PP is often modified to enhance specific properties.

Copolymers: Ethylene is copolymerized to create Impact Copolymer (ICP) for better toughness at low temperatures or Random Copolymer for improved clarity and flexibility.

Additives: These include nucleating agents (to increase crystallization rate, improve clarity and stiffness), stabilizers (against UV and thermal degradation), flame retardants, colorants, and fillers like talc or glass fiber (dramatically increasing stiffness and heat deflection temperature).

3. The Injection Moulding Process: A Step-by-Step Breakdown

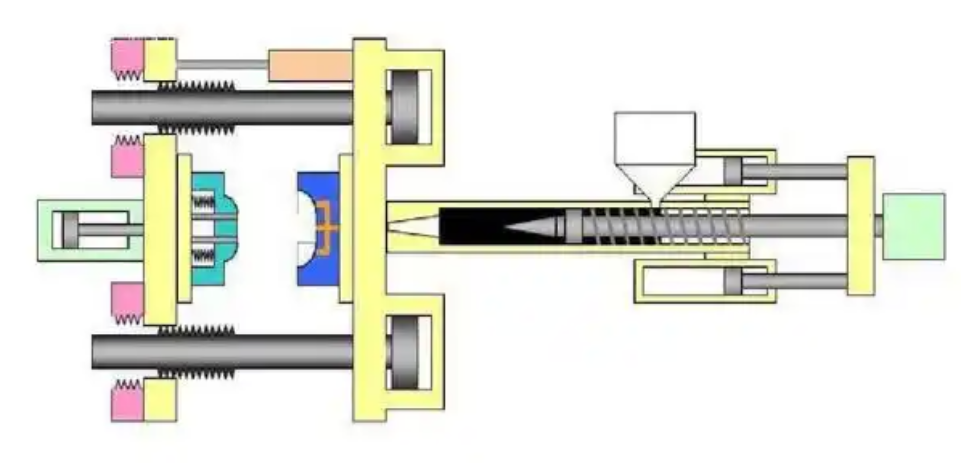

The injection moulding process for PP is a cyclical operation consisting of four main stages:

Stage 1: Clamping

The two halves of the mould are securely closed and held together under high pressure by the clamping unit. Tonnage (clamping force) must be sufficient to resist the immense pressure of the injected melt (typically 500-1500 tonnes for medium-sized parts).

Stage 2: Injection

PP granules are fed from the hopper into the heated barrel. A rotating screw conveys the material forward, where it is heated by both external heaters and internal shear friction until it becomes a homogeneous melt. Once a sufficient “shot” volume is accumulated at the screw tip, the screw acts as a plunger. It injects the molten PP at high speed and pressure into the mould cavity through a runner system and gate.

Stage 3: Cooling & Holding

Once the cavity is filled, the holding/packing phase begins. Additional melt is packed into the cavity to compensate for material shrinkage as it begins to cool and solidify. The part remains in the mould under pressure until the gate solidifies, after which it continues to cool. Cooling time often constitutes the majority of the total cycle time. Efficient cooling channel design is critical.

Stage 4: Ejection

After sufficient cooling, the mould opens, and ejector pins push the solidified part out of the cavity. The mould then closes, and the cycle repeats.

4. Critical Processing Parameters for PP

Melt Temperature: Typically ranges from 200°C to 280°C, depending on the grade (e.g., higher for filled grades). Too low a temperature leads to poor flow and high viscosity; too high risks polymer degradation.

Mould Temperature: A crucial parameter for semi-crystalline PP. Recommended range is 40°C to 80°C.

A higher mould temperature promotes slower crystallization, resulting in higher crystallinity, better surface finish (gloss), improved dimensional stability, and reduced molded-in stress. However, it increases cycle time.

A lower mould temperature speeds up the cycle but can lead to lower crystallinity, poorer surface finish, and higher post-mould shrinkage.

Injection Speed & Pressure:

Speed: Fast injection is generally beneficial for PP as it minimizes premature freezing, ensures good cavity fill, and can produce a better surface gloss. However, it can lead to jetting or shear-related issues in delicate parts.

Pressure: Must be high enough to fill and pack the cavity completely but optimized to avoid flash, over-packing, and excessive residual stress.

Holding/Packing Pressure and Time: This is key to managing shrinkage and sink marks. Holding pressure is usually 50-80% of injection pressure, applied until the gate seals. Insufficient holding leads to sink marks and voids; excessive holding can cause part sticking and stress.

5. Part and Mould Design Considerations

Good design is essential for a successful, cost-effective moulding project.

Wall Thickness: Maintain uniform wall thickness (typically 1.5mm – 3.0mm for PP) to ensure even cooling and prevent sink marks, warpage, and internal stresses. Thick sections should be cored out.

Ribs and Bosses: Use ribs (thickness ~50-60% of the adjoining wall) to increase stiffness without creating thick sections. Bosses for screw assembly should be designed with proper gussets and careful attention to sink marks.

Draft Angles: Incorporate draft angles (minimum 1°-2°) on all walls parallel to the mould opening direction to facilitate easy ejection and prevent drag marks.

Radii and Corners: Use generous radii on all corners to improve material flow, reduce stress concentration, and strengthen the part.

Gate Design: The gate location is paramount. It should be positioned to ensure balanced flow, minimize weld lines (which are weak in PP), and allow for easy degating. Common gate types for PP include submarine gates, edge gates, and hot runner direct gates.

6. Common Defects and Troubleshooting in PP Moulding

Even with a good design, defects can occur. Here are common PP-specific issues:

Sink Marks: Localized depressions on the surface, often over ribs or thick sections.

Cause: Insufficient packing/cooling of thick areas.

Solution: Increase holding pressure/time; reduce melt temperature; optimize part design (core out thick sections).

Warpage: Distortion of the part after ejection.

Cause: Non-uniform cooling or differential shrinkage due to molecular/crystalline orientation, especially in semi-crystalline PP.

Solution: Ensure uniform cooling (check mould temperature); optimize gate location to promote balanced flow; lower mould temperature to reduce crystallinity gradients.

Weld Lines: Visible lines where melt fronts meet and don’t fuse perfectly.

Cause: Obstacles like holes or multiple gates in the flow path.

Solution: Increase melt temperature and injection speed; relocate gates; improve venting at weld line areas.

Short Shot: Incomplete filling of the mould cavity.

Cause: Insufficient material, low melt temp, low injection speed/pressure, or blocked venting.

Solution: Check all the above parameters; ensure proper venting.

7. Advancements and Future Outlook

The field of PP injection moulding continues to evolve:

High-Speed, Automated Moulding: For thin-walled packaging, cycles are measured in seconds, integrated with robotics for part handling, inspection, and assembly.

Micro-Moulding: Producing extremely small, high-precision PP components for medical and micro-engineering applications.

Multi-Material/Overmoulding: Using PP as a substrate overmoulded with a TPE (Thermoplastic Elastomer) for soft-touch grips, combining rigidity with elasticity.

Sustainable PP: The use of post-consumer recycled (PCR) PP and bio-based PP is growing rapidly. Processing these materials often requires adjustments to account for varied melt flow and potential contamination. The industry is moving strongly towards a circular economy model.

8. Conclusion

Polypropylene injection moulding is a cornerstone of modern manufacturing, a perfect synergy of material science and precision engineering. Its success hinges on a deep understanding of PP’s semi-crystalline nature, meticulous control of the processing parameters, and intelligent part and mould design. As technology advances towards greater automation, miniaturization, and sustainability, PP’s role is set to expand even further. For engineers and designers, mastering the intricacies of PP injection moulding remains a vital skill for turning innovative concepts into the durable, functional, and economical products that define our everyday world.