PET injection molding

- Home

- / Material /

- PET injection molding

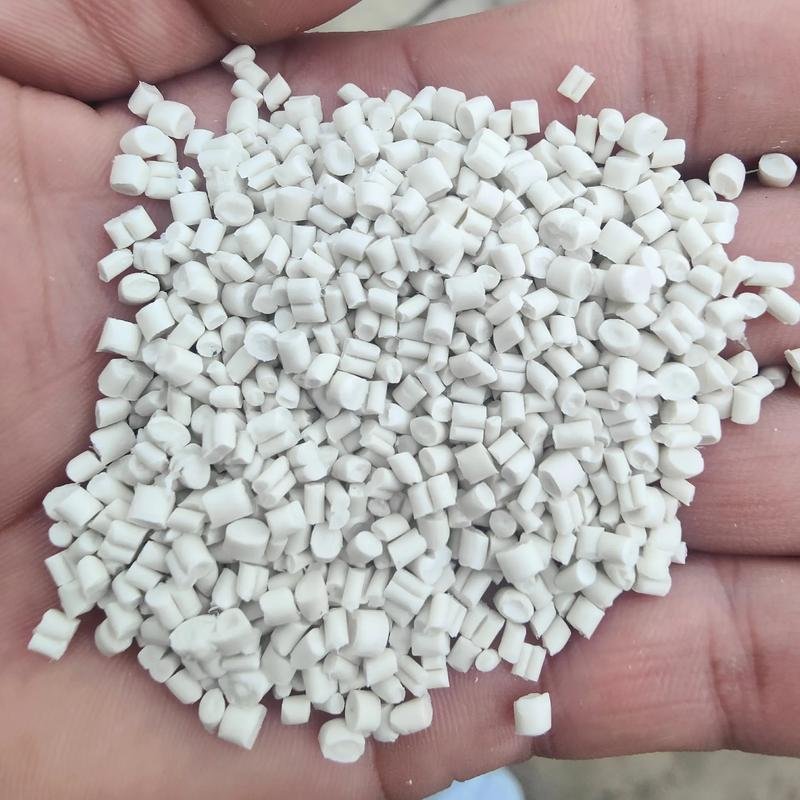

Polyethylene Terephthalate (PET) Injection Moulding: Mastering the Versatile Packaging Polymer

1. Introduction: The World’s Most Recognized Polymer

Polyethylene Terephthalate (PET) stands as one of the most ubiquitous and economically significant thermoplastics globally, with annual production exceeding 70 million tons. While famously known for beverage bottle applications, PET’s injection moulding capabilities extend far beyond packaging into automotive, electrical, consumer goods, and technical applications. First commercialized in the 1940s for synthetic fibers, PET has evolved into a sophisticated engineering material with distinct processing characteristics that challenge conventional injection moulding approaches.

This comprehensive guide explores the intricate world of PET injection moulding, examining the material’s unique crystallization behavior, specialized drying requirements, and processing techniques that enable its use in everything from precision automotive components to durable consumer products. We will uncover why PET, despite its processing challenges, remains a material of choice for applications demanding clarity, strength, and recyclability.

2. Material Science: Understanding PET Chemistry

Chemical Fundamentals:

PET is a semi-crystalline thermoplastic polyester synthesized through polycondensation of terephthalic acid (PTA) or dimethyl terephthalate (DMT) with ethylene glycol (EG). This chemical structure provides:

Key Structural Characteristics:

Aromatic Rings: From terephthalate units, providing rigidity

Ester Linkages: Enabling crystallization and chemical reactivity

Ethylene Units: Providing some molecular flexibility

Polar Nature: Contributing to moisture sensitivity

PET Material Grades:

| Grade Type | Intrinsic Viscosity (IV) | Key Characteristics | Applications |

|---|---|---|---|

| Bottle Grade | 0.70-0.85 dl/g | High molecular weight, clarity | Beverage bottles |

| Injection Grade | 0.80-1.00 dl/g | Balanced flow/crystallization | Technical parts |

| High IV Grades | 1.00-1.20 dl/g | Higher strength, slower crystallization | Engineering parts |

| Copolymer PET | Modified | Reduced crystallization rate | Clear thin-walled parts |

| Reinforced PET | Various | Glass/carbon fiber filled | Structural components |

| PETG | Glycol-modified | Amorphous, excellent clarity | Medical, displays |

Property Comparison:

| Property | PET (Crystalline) | PETG (Amorphous) | Advantage |

|---|---|---|---|

| Density | 1.33-1.38 g/cm³ | 1.27 g/cm³ | Lighter amorphous version |

| Tensile Strength | 55-75 MPa | 50-55 MPa | Higher crystalline strength |

| HDT @ 1.82 MPa | 65-85°C | 70-75°C | Similar thermal resistance |

| Light Transmission | 85-90% | 88-92% | Excellent clarity both types |

| Chemical Resistance | Excellent | Good | Better crystalline resistance |

| Recyclability | Excellent | Good | Established recycling streams |

3. Material Preparation: The Critical Drying Process

Extreme Drying Imperatives:

PET is highly hygroscopic with moisture absorption up to 0.4% at equilibrium. Improper drying causes irreversible damage:

Drying Specifications:

Target Moisture: <0.005% (50 ppm) for injection moulding

Drying Temperature: 120-140°C (248-284°F)

Drying Time: 4-6 hours minimum

Dew Point: -40°C (-40°F) or lower mandatory

Hopper Design: Closed-loop dehumidifying dryers essential

Consequences of Insufficient Drying:

Hydrolytic Degradation: Water cleaves ester bonds, reducing molecular weight

IV Drop: Intrinsic viscosity reduction directly affects mechanical properties

Surface Defects: Splay marks, streaks, bubbles

Property Loss: Up to 50% reduction in impact strength possible

Processing Issues: Unstable viscosity, inconsistent filling

Material Handling Protocol:

Storage Conditions: Below 30°C, <30% relative humidity

Container Management: Original foil-lined bags until use

Exposure Time: Maximum 1 hour in production environment

Regrind Management: Maximum 20-25% with proper drying

IV (Intrinsic Viscosity) Control:

Measurement: Standard method for molecular weight determination

Acceptable Range: ±0.02 dl/g variation maximum

Testing Frequency: Every batch for critical applications

Correlation: Direct relationship with mechanical properties

Colorant and Additive Integration:

Masterbatches: PET-compatible carriers required

Nucleating Agents: For controlled crystallization

UV Stabilizers: For outdoor applications

Antistatic Additives: For electronic applications

4. Injection Moulding Machine Requirements

Specialized Equipment Configuration:

Temperature Capability:

Processing Range: 260-290°C (500-554°F)

Temperature Control: ±2°C precision throughout system

Heating Zones: Minimum 4 zones with PID control

Insulation: To maintain consistent melt temperature

Screw Design Requirements:

Type: General purpose with gradual compression

L/D Ratio: 20:1 to 24:1

Compression Ratio: 2.0:1 to 2.5:1

Check Valve: Sliding ring type with minimal residence

Screw Tip: Mixing elements for color dispersion

Surface Treatment: Hard chrome for wear resistance

Barrel and Nozzle System:

Barrel Material: Standard with corrosion protection

Capacity: 50-80% of machine rating optimal

Nozzle Type: Open or shut-off for drool prevention

Thermocouples: Accurate and regularly calibrated

Clamping System:

Clamp Force: 3-5 tons per square inch

Platen Parallelism: Critical for consistent filling

Ejection System: Adequate for part removal

Tie Bar Clearance: For mold installation

Special Features for PET:

Decompression: To prevent drooling

Cushion Control: Consistent cushion size critical

Shot Size Control: Precise for consistent crystallization

Back Pressure Control: For melt homogeneity

Auxiliary Equipment:

High-Capacity Dryers: For continuous production

Mold Temperature Controllers: Precise ±1°C control

Robotics: For part handling and quality assurance

Chillers: For controlled cooling

5. Processing Parameters and Optimization

Temperature Parameters:

| Process Zone | Temperature Range | Critical Notes |

|---|---|---|

| Rear Barrel | 260-275°C (500-527°F) | Gentle melting to prevent degradation |

| Middle Zones | 270-285°C (518-545°F) | Main melting and homogenization |

| Front Zone | 275-290°C (527-554°F) | Final melt preparation |

| Nozzle | 275-290°C (527-554°F) | Match to melt temperature |

| Melt Temperature | 270-285°C (518-545°F) | Critical for crystallization control |

| Mold Temperature | 10-140°C (50-284°F) | Wide range depending on application |

Mold Temperature Strategy:

| Application | Mold Temperature | Crystallinity | Resulting Properties |

|---|---|---|---|

| Clear Parts | 10-30°C (50-86°F) | <5% | Optical clarity |

| Technical Parts | 80-100°C (176-212°F) | 20-30% | Balanced properties |

| Engineering Parts | 120-140°C (248-284°F) | 30-40% | Maximum crystallinity |

| Fast Cycling | 10-20°C (50-68°F) | Very low | Quick cycles, lower properties |

Injection Phase Optimization:

Injection Speed:

Fast injection recommended

Prevents premature freezing

Reduces orientation

Injection Pressure: 800-1400 bar

Switchover: 95-98% cavity fill by volume

Back Pressure: 5-10 bar minimum

Holding/Packing Phase:

Pressure: 40-60% of injection pressure

Time: Critical – until gate freeze (5-15 seconds)

Function: Compensates for shrinkage (1.2-2.0%)

Multi-Stage: Often beneficial

Cooling Strategy:

Cooling Time: 15-40 seconds per mm thickness

Ejection Temperature: Below 80°C for amorphous parts

Crystallization Control: Through mold temperature

Cycle Time: Typically 20-60 seconds

6. Crystallization Control in PET Processing

Understanding PET Crystallinity:

Maximum Crystallinity: 30-40% achievable

Glass Transition (Tg): 70-80°C (158-176°F)

Crystallization Temperature: 120-140°C (248-284°F)

Melting Point: 245-260°C (473-500°F)

Factors Affecting Crystallinity:

| Factor | Effect on Crystallinity | Process Control |

|---|---|---|

| Mold Temperature | Higher temp = higher crystallinity | Primary control method |

| Cooling Rate | Slower cooling = higher crystallinity | Controlled through cooling system |

| Nucleating Agents | Increase crystallization rate | Material formulation |

| Molecular Orientation | Higher orientation = faster crystallization | Injection speed control |

| Part Thickness | Thicker sections = higher crystallinity | Design consideration |

Processing for Specific Crystallinity Levels:

Amorphous PET (Clear Parts):

Mold Temperature: <30°C (86°F)

Cooling Rate: Very fast

Applications: Clear containers, displays

Benefits: Optical clarity, transparency

Semi-Crystalline PET (Technical Parts):

Mold Temperature: 80-100°C (176-212°F)

Cooling Rate: Moderate

Applications: Automotive, electrical components

Benefits: Better chemical resistance, higher HDT

Highly Crystalline PET (Engineering Parts):

Mold Temperature: 120-140°C (248-284°F)

Post-Mould Annealing: Often required

Applications: Structural components

Benefits: Maximum mechanical properties

Crystallinity Measurement Methods:

DSC Analysis: Most common method

Density Gradient: For quick quality control

XRD: For crystal structure analysis

FTIR Spectroscopy: For chemical analysis

7. Tooling Design for PET Moulding

Mold Material Selection:

Production Molds: Tool steels P20, H13, or stainless steels

Surface Hardness: 48-52 HRC minimum

Corrosion Resistance: Chrome plating recommended

Surface Finish: SPI A-1 to B-3 depending on application

Runner System Design:

Full Round Runners: 6-10mm diameter minimum

Runner Layout: Short and direct preferred

Cold Slug Wells: Essential at runner ends

Hot Runner Systems: Increasingly common for high volume

Gate Design Considerations:

| Gate Type | Best For | Design Considerations |

|---|---|---|

| Edge Gates | Most applications | Easy trimming, good control |

| Pin Gates | Automatic degating | Small marks, good for cosmetic parts |

| Hot Runner | Multi-cavity molds | Material savings, better control |

| Valve Gates | Sequential filling | Eliminate weld lines |

| Submarine Gates | Hidden gates | Cosmetic surfaces |

Cooling System Design:

Critical Importance: Controls crystallization and cycle time

Channel Design: Follow part contours closely

Temperature Control: ±3°C uniformity target

Circuit Layout: Balanced for uniform cooling

Baffles/Bubblers: For difficult-to-cool areas

Venting System:

Vent Depth: 0.020-0.035mm

Vent Width: 6-12mm

Placement: End of fill and weld line areas

Importance: Prevents burning and short shots

Ejection System:

Ejector Pins: Standard sizes typically adequate

Surface Finish: Polish to prevent marks

Ejection Force: Moderate for PET

Air Ejection: Option for cosmetic parts

Surface Finishes:

Optical Surfaces: SPI A-1 mirror finish

Textured Surfaces: Available but affects crystallization

Draft Angles: 1-2° minimum standard

8. Part Design Guidelines for PET Components

Wall Thickness Principles:

General Range: 1.0-4.0mm

Optimal Thickness: 1.5-2.5mm

Uniformity: Critical (maximum 25% variation)

Minimum Thickness: 0.5mm possible with optimized processing

Thick Sections: Core out to prevent sink marks

Radii and Corner Design:

Internal Radii: Minimum 0.5 times wall thickness

External Radii: Internal radius plus wall thickness

Stress Concentration: Avoid sharp corners

Transition Design: Gradual changes (3:1 maximum ratio)

Rib and Boss Design:

Rib Thickness: 40-60% of adjacent wall

Rib Height: Maximum 3 times wall thickness

Boss Design: Should be cored and connected with ribs

Draft Angles: 1-2° per side minimum

Draft Angle Requirements:

Standard Applications: 1-2° per side

Textured Surfaces: Add 1° per 0.025mm texture depth

Deep Draw Parts: Additional draft may be needed

Clear Parts: Minimal draft for optical surfaces

Living Hinge Design:

PET Capability: Good for certain applications

Design Guidelines:

Thickness: 0.25-0.50mm

Width: 1.5-3.0mm

Orientation: Perpendicular to flow direction

Radius: Generous at hinge ends

Assembly Features:

Snap-fits: Good performance with proper design

Threads: Molded-in possible

Press-fits: Careful interference calculations

Ultrasonic Welding: Excellent for PET

Solvent Bonding: Good with proper solvents

9. Specialized Applications and Processing

Packaging Applications:

Preforms for Bottles: High-speed production (up to 144 cavities)

Food Containers: Microwaveable, clear or colored

Cosmetic Packaging: Jars, tubes, dispensers

Pharmaceutical: Blister packs, medicine containers

Automotive Components:

Electrical Connectors: For underhood applications

Sensor Housings: Engine management systems

Interior Trim: Components requiring chemical resistance

Lighting: Reflectors, lens components

Electrical and Electronics:

Connectors: SMT and through-hole types

Switch Housings: For various applications

Coil Bobbins: For transformers and motors

Insulating Components: High dielectric strength

Consumer Products:

Housewares: Containers, utensils, organizers

Appliance Parts: Housings, components

Sporting Goods: Components requiring durability

Furniture: Structural and decorative elements

Medical Applications:

Device Housings: Durable and sterilizable

Laboratory Ware: Trays, containers

Surgical Instruments: Single-use components

Diagnostic Devices: Housings and components

Advanced Processing Techniques:

Injection Stretch Blow Moulding (ISBM):

Process: Injection mould preform → Heat → Stretch blow

Applications: Bottles, containers

Advantages: Biaxial orientation, improved properties

Equipment: Specialized ISBM machines

Multi-Layer Moulding:

Barrier Layers: EVOH, nylon for improved barrier

Recycled Content: Sandwich layers for sustainability

Color Effects: Aesthetic multi-layer designs

Equipment: Co-injection or sequential injection

Microcellular Foam Moulding:

Benefits: Weight reduction, material savings

Applications: Thick-section parts

Challenges: Surface quality maintenance

Equipment: Specialized injection units

10. Quality Control and Testing

Material Testing Protocols:

Intrinsic Viscosity (IV) Testing:

Method: ASTM D4603 or ISO 1628-5

Frequency: Every batch for critical applications

Acceptance Criteria: ±0.02 dl/g from specification

Importance: Direct correlation with mechanical properties

Thermal Analysis:

DSC: Melting point, crystallinity percentage

TGA: Thermal stability, decomposition temperature

DMA: Dynamic mechanical properties

HDT/Vicat: Heat deflection and softening points

Mechanical Testing:

Tensile Properties: ASTM D638

Impact Resistance: ASTM D256 (Izod/Charpy)

Flexural Properties: ASTM D790

Environmental Stress Crack Resistance: ASTM D1693

Optical Properties:

Haze and Transmission: ASTM D1003

Color Measurement: Spectrophotometer

Clarity: For packaging applications

Gloss: Surface finish assessment

Barrier Properties (Packaging):

Oxygen Transmission Rate: ASTM D3985

Carbon Dioxide Transmission: ASTM F2476

Water Vapor Transmission: ASTM F1249

Test Conditions: 23°C/50% RH standard

Process Control Parameters:

Melt Temperature: Continuous monitoring

IV Retention: Regular testing of processed material

Part Weight: Statistical process control

Cycle Time: Consistency monitoring

Regulatory Compliance:

FDA Food Contact: 21 CFR 177.1630

EU Food Contact: Regulation (EU) 10/2011

Recycled Content: For sustainability claims

Heavy Metals: Compliance with RoHS, etc.

11. Troubleshooting Common PET Defects

| Defect | Root Causes | Corrective Actions | Prevention |

|---|---|---|---|

| Splay/Silver Streaks | Moisture, contamination | Verify drying (<50 ppm), clean equipment | Proper material handling |

| IV Drop | Hydrolysis, excessive heat | Improve drying, reduce temperatures | Strict moisture control |

| Poor Clarity | Crystallization, contamination | Lower mold temperature, clean material | Control crystallization |

| Weld Lines | Multiple flow fronts, low temp | Increase temperature, relocate gates | Single gate when possible |

| Sink Marks | Insufficient packing, thick sections | Increase holding pressure/time, modify design | Uniform wall design |

| Warpage | Non-uniform cooling, high stress | Improve cooling uniformity, annealing | Balanced cooling design |

| Brittleness | Low IV, excessive crystallinity | Check material IV, reduce mold temperature | Material quality control |

| Discoloration | Thermal degradation, contamination | Lower temperatures, clean equipment | Temperature control |

Material-Specific Issues:

Hydrolytic Degradation: Permanent molecular weight reduction

Crystallization Control: Critical for property consistency

Orientation Effects: Affects shrinkage and properties

Thermal Sensitivity: Narrow processing window

Preventive Measures:

Material Quality Assurance: Regular IV testing

Process Documentation: Complete parameter records

Equipment Maintenance: Regular screw and barrel inspection

Operator Training: For proper material handling

12. Sustainability and Recycling

Recycling Infrastructure:

Mechanical Recycling: Well-established for PET

Process: Collection → Sorting → Washing → Flaking → Reprocessing

rPET Grades: Various quality levels available

Applications: Fibers, strapping, bottles, engineering parts

Chemical Recycling:

Depolymerization: Back to monomers (PTA and EG)

Glycolysis: Partial depolymerization

Methanolysis: To DMT and EG

Advantages: Virgin-quality material recovery

Energy Recovery:

Calorific Value: 23 MJ/kg

Waste-to-Energy: Option for contaminated material

Environmental Compliance: Proper emissions control

Sustainable Manufacturing:

Lightweighting: Reducing material usage

Energy Efficiency: Optimized processing parameters

Water Conservation: In washing and cooling processes

Renewable Energy: Solar/wind for manufacturing

Industry Initiatives:

EPR Programs: Extended Producer Responsibility

Design for Recycling: Mono-material designs

Closed-Loop Systems: Bottle-to-bottle recycling

Certification Programs: For recycled content

Regulatory Framework:

Recycled Content Mandates: Increasing globally

Food Contact Approval: For rPET in many regions

Environmental Claims: Third-party verification required

Carbon Accounting: For sustainability reporting

13. Future Trends and Innovations

Material Innovations:

Enhanced Barrier PET: For extended shelf life

Bio-based PET: From renewable resources

High-Temperature PET: For engineering applications

Self-Reinforcing PET: Through molecular design

Processing Advancements:

Industry 4.0 Integration: Smart manufacturing systems

Additive Manufacturing: 3D printing with PET

Micro-moulding: For miniature components

Hybrid Processes: Combining different technologies

Application Expansion:

Electric Vehicles: Battery components, connectors

Advanced Packaging: Active and intelligent packaging

Medical Devices: Implantable-grade materials

Construction: Structural applications

Sustainability Developments:

Advanced Recycling: Improved efficiency and quality

Carbon Capture: Integration with PET production

Circular Design: Complete lifecycle optimization

Biodegradable Options: For specific applications

Market and Regulatory Trends:

Global Harmonization: Of recycling standards

Cost Reduction: Through improved efficiency

Regulatory Evolution: Changing requirements

Supply Chain Optimization: For sustainability

14. Conclusion: Mastering Versatile Polymer Processing

PET injection moulding represents a sophisticated manufacturing discipline requiring:

Material Understanding: Deep knowledge of PET chemistry and behavior

Process Control: Precise management of crystallization and drying

Equipment Capability: Properly configured machinery and tooling

Quality Commitment: Uncompromising standards for diverse applications

Sustainability Focus: Environmental responsibility throughout lifecycle

The future of PET processing lies in expanding its capabilities beyond traditional packaging into high-value technical applications while improving sustainability through advanced recycling and renewable materials. As circular economy principles become increasingly important, PET’s established recycling infrastructure positions it well for continued growth and innovation.

For manufacturers, PET offers opportunities across multiple market segments with varying technical requirements. The investment in specialized knowledge and equipment is rewarded with access to markets ranging from high-volume packaging to precision engineering components.

As technology advances and environmental considerations become more critical, those who have mastered PET processing will be positioned to lead in sustainable manufacturing. The journey requires technical expertise and commitment to quality, but the destination – producing versatile, high-performance components with excellent environmental credentials – justifies the effort