ABS injection molding

- Home

- / Material /

- ABS injection molding

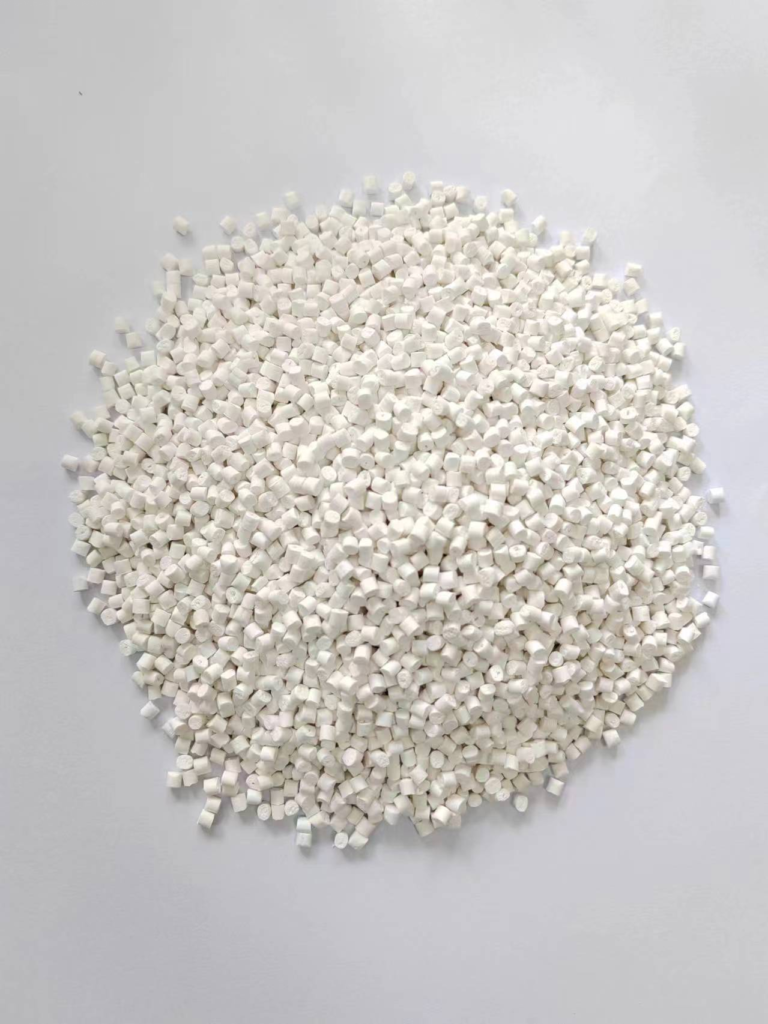

Acrylonitrile Butadiene Styrene (ABS) Injection Moulding: The Complete Technical Guide

1. Introduction: The Engineering Thermoplastic Standard

Acrylonitrile Butadiene Styrene, universally known as ABS, represents the quintessential engineering thermoplastic, perfectly balancing mechanical properties, processability, and cost-effectiveness. Since its commercial introduction in the 1950s, ABS has become indispensable across industries, valued for its unique combination of strength, rigidity, impact resistance, and superb surface finish. Injection moulding, as ABS’s primary processing method, enables the mass production of dimensionally stable, high-quality parts that meet stringent technical and aesthetic requirements.

From the iconic LEGO brick to critical automotive components, ABS injection moulding demonstrates remarkable versatility. This comprehensive guide explores the material science, processing parameters, design considerations, and advanced techniques that define modern ABS moulding practices, providing engineers and technicians with the knowledge to optimize their manufacturing processes.

2. Material Science: The ABS Terpolymer Advantage

ABS derives its balanced properties from its three constituent monomers:

Chemical Composition and Morphology

Acrylonitrile (15-35%): Provides chemical resistance, thermal stability, and rigidity

Butadiene (5-30%): Contributes toughness and impact resistance through rubber particle dispersion

Styrene (40-60%): Offers processability, gloss, and rigidity

This unique structure creates a two-phase system:

Continuous SAN Phase: Styrene-acrylonitrile copolymer matrix

Dispersed Rubber Phase: Polybutadiene particles that absorb and dissipate impact energy

Key ABS Grades and Their Applications:

| Grade Type | Key Characteristics | Typical Applications |

|---|---|---|

| General Purpose | Balanced properties, good processability | Consumer products, housings, toys |

| High Impact | Enhanced toughness via higher butadiene | Automotive interiors, protective equipment |

| Heat Resistant | Improved thermal stability (HDT up to 110°C+) | Automotive underhood components, electrical parts |

| Plating Grade | Modified for excellent metal adhesion | Automotive grilles, plumbing fixtures, decorative trim |

| Flame Retardant | UL94 V-0 and V-2 ratings | Electrical enclosures, computer components |

| Transparent | Optical clarity variants | Displays, lenses, transparent covers |

Material Properties Overview:

Density: 1.04-1.07 g/cm³

Melt Flow Index: 10-60 g/10min (varies by grade)

Tensile Strength: 40-50 MPa

Notched Izod Impact: 200-400 J/m

Heat Deflection Temperature: 90-105°C @ 1.82 MPa

3. Material Handling and Pre-processing

Critical Drying Requirements

Unlike many commodity plastics, ABS is hygroscopic and requires meticulous drying:

Moisture Content Target: <0.1% (typically 0.02-0.05% for optimal processing)

Drying Conditions: 80-85°C for 2-4 hours (avoid exceeding 90°C to prevent agglomeration)

Dew Point: -40°C or lower recommended for desiccant dryers

Consequences of Insufficient Drying: Splay marks, bubbles, reduced mechanical properties, poor surface finish

Regrind Management

Regrind Percentage: Typically 20-30% maximum with virgin material

Considerations: Thermal history affects color stability and properties

Blending: Ensure homogeneous mixing of virgin and regrind

Drying Regrind: Often requires longer drying times than virgin material

Colorant Integration

Excellent pigment acceptance

Masterbatch carriers should be compatible SAN or ABS-based

For critical colors: Pre-compounded colors often preferable to dry blending

4. Injection Moulding Machine Requirements

Screw and Barrel Specifications

Screw Type: General purpose screw with compression ratio of 2.0:1 to 2.5:1

L/D Ratio: 20:1 is standard; 24:1 provides better mixing and melt homogeneity

Check Valve: Sliding ring type recommended for precise shot control

Barrel Capacity: Shot size should be 30-80% of machine capacity for optimal plastication

Nozzle Selection

Open Nozzle: Standard for most applications

Shut-off Nozzle: Recommended for hot runner systems or when dealing with drool

Nozzle Temperature: Typically 5-10°C above melt temperature

Clamping System

Tonnage Calculation: 2-5 tons per square inch of projected area

Platen Parallelism: Critical for uniform part filling and minimal flash

Ejection System: Adequate stroke and force for part removal

5. Processing Parameters and Optimization

Temperature Settings by Grade:

| Parameter | General Purpose ABS | High Heat ABS | Flame Retardant ABS |

|---|---|---|---|

| Rear Zone | 180-200°C | 200-220°C | 190-210°C |

| Middle Zones | 200-230°C | 220-240°C | 210-230°C |

| Front Zone | 220-240°C | 230-250°C | 220-240°C |

| Nozzle | 220-240°C | 230-250°C | 220-240°C |

| Melt Temp | 220-240°C | 230-250°C | 220-240°C |

| Mould Temp | 50-80°C | 60-90°C | 50-70°C |

Injection Phase Parameters

Injection Speed: Medium to fast (prevents premature freezing but avoids jetting)

Injection Pressure: 800-1500 bar (adjusted based on flow length and wall thickness)

Switchover Point: 95-98% cavity fill by volume (to prevent overpacking)

Holding/Packing Phase

Pressure: 40-70% of injection pressure

Time: Until gate freeze (typically 5-15 seconds depending on part thickness)

Function: Compensates for shrinkage, prevents sink marks and voids

Cooling and Cycle Time Optimization

Cooling Time: Represents 50-70% of total cycle time

Ejection Temperature: 80-90°C (sufficiently below HDT to prevent distortion)

Total Cycle Time: Typically 30-90 seconds depending on wall thickness

6. Tooling Design for ABS Moulding

Mould Material Selection

Production Moulds: P20, H13, or stainless steels for corrosion resistance

Prototype Moulds: Aluminum (7075-T6 or similar) for rapid turnaround

Surface Treatments: Chrome plating or nitriding for wear resistance and release

Runner System Design

Cold Runners: Full round preferred (minimum 4-8mm diameter)

Hot Runners: Valve-gated systems recommended for cosmetic parts

Runner Balancing: Critical for multi-cavity moulds

Gate Design Considerations

Gate Types: Edge, submarine, tab, or direct (hot runner) gates most common

Gate Size: Typically 0.5-1.5mm thick, width depends on part size

Location: Position to minimize weld lines and maximize strength

Cooling System Design

Channel Diameter: 8-12mm standard

Layout: Follow part contours as closely as possible

Temperature Control: ±2°C uniformity target across mould surface

Venting Requirements

Vent Depth: 0.015-0.025mm

Vent Width: 6-12mm

Location: End of fill and weld line areas

Importance: Prevents burning, short shots, and poor surface finish

7. Part Design Guidelines for ABS

Wall Thickness Principles

General Range: 1.5-4.0mm (optimal: 2.0-2.5mm)

Uniformity: Critical to prevent warpage (maximum variation: ±15%)

Thick Sections: Core out to maintain uniform thickness

Minimum Thickness: 0.75mm achievable with optimized processing

Ribs and Bosses Design

Rib Thickness: 50-60% of adjacent wall

Rib Height: Maximum 3 times wall thickness

Boss Design: Should be cored and connected with ribs to main walls

Draft on Ribs: 0.5-1.0° per side minimum

Corner Design

Internal Radii: Minimum 0.5 times wall thickness

External Radii: Internal radius plus wall thickness

Benefits: Reduces stress concentration, improves flow

Draft Angles

Textured Surfaces: 3° per side minimum (plus 1° per 0.025mm texture depth)

Smooth Surfaces: 1-2° per side minimum

Deep Draw Parts: Additional draft required

Snap-Fit Design

Cantilever Snap-Fits: Most common for ABS

Strain Limit: 5-6% maximum for repeated assembly

Engagement Length: 0.5-2.0mm typically

Lead-in Angles: 15-30° for easy assembly

8. Troubleshooting Common ABS Defects

| Defect | Primary Causes | Corrective Actions |

|---|---|---|

| Splay/Silver Streaks | Moisture contamination, overheating, excessive shear | Proper drying (80-85°C, 2-4hrs), reduce melt temp, lower injection speed |

| Weld Lines | Multiple flow fronts, low melt temp, poor gate location | Increase melt temp and injection speed, relocate gates, add flow leaders |

| Sink Marks | Insufficient packing, thick sections, high melt temp | Increase holding pressure/time, core out thick areas, lower melt temp |

| Warpage | Non-uniform cooling, differential shrinkage, residual stress | Improve cooling uniformity, adjust mould temp, optimize holding pressure |

| Burning | Trapped air, excessive speed, inadequate venting | Add/enlarge vents, reduce injection speed, lower melt temperature |

| Short Shots | Insufficient material, low temp/pressure, restricted flow | Check material feed, increase temp/pressure, enlarge gates/runners |

| Jetting | Gate too small, injection too fast, melt temp too low | Enlarge gate, reduce injection speed, increase melt temperature |

| Delamination | Material contamination, excessive moisture, incompatible regrind | Clean equipment, ensure proper drying, reduce regrind percentage |

Material-Specific Issues:

Thermal Degradation: Occurs above 260°C – reduce temperatures

Color Shift: Can occur with excessive regrind or thermal history – control regrind percentage

Stress Cracking: From chemical exposure or excessive molded-in stress – adjust design/process

9. Secondary Operations and Finishing

Machining and Assembly

Excellent machinability: drilling, tapping, milling, turning

Joining Methods: Ultrasonic welding, vibration welding, solvent bonding (with acetone or MEK), adhesive bonding, mechanical fasteners

Design for Assembly: Incorporate alignment features, access for tools

Surface Finishing Options

Painting:

Requires proper surface preparation (cleaning, possibly light abrasion)

Adhesion promoters sometimes necessary

Wide range of paint types compatible

Plating:

Special plating-grade ABS required

Process: Etching → Catalyzation → Electroless nickel → Electroplating

Applications: Automotive, plumbing, decorative hardware

Texture and Finish:

Excellent replication of mould textures

SPI standards A-1 to D-3 commonly specified

Matte finishes help hide flow lines and imperfections

Decoration Techniques

Pad printing, hot stamping, laser marking, in-mould decoration

Each method requires specific design considerations

10. Advanced Processing Techniques

Two-Shot/Overmoulding

ABS commonly used as substrate for TPE/TPU overmoulding

Applications: Soft-grip handles, seals, cosmetic two-tone parts

Requires specialized equipment and precise process control

Gas-Assisted Injection Moulding

Benefits: Reduced weight, elimination of sink marks, lower clamp force

Particularly effective for thick-section parts like handles and beams

Process design critical for consistent channel formation

In-Mould Decoration (IMD)

Film insert moulding for high-quality graphics

Applications: Automotive interiors, appliance panels, control interfaces

Requires precise film handling and special mould designs

Microcellular Foam Moulding (MuCell®)

Benefits: Weight reduction, reduced sink marks, faster cycle times

Challenges: Surface finish considerations, strength reduction

Applications: Thick structural parts, large panels

11. Quality Control and Testing

Process Monitoring

Key Parameters: Melt temperature, injection pressure, cushion size, cycle time

Statistical Process Control (SPC): Essential for consistent quality

Real-time Monitoring: Pressure transducers, temperature sensors

Material Testing

Melt Flow Rate: ASTM D1238 (indicates molecular weight and processability)

Mechanical Properties: Tensile (ASTM D638), impact (ASTM D256), flexural (ASTM D790)

Thermal Analysis: HDT (ASTM D648), Vicat softening point (ASTM D1525)

Flammability: UL94 vertical/horizontal burn tests

Part Validation

Dimensional Checks: CMM, optical comparators, functional gauges

Surface Quality: Visual inspection standards (e.g., SPI standards)

Performance Testing: Fit, function, assembly validation

Environmental Testing: Heat aging, chemical resistance, weathering

12. Sustainability and Future Trends

Recycling and Sustainability

Post-Consumer Recycling: Increasing but challenging due to mixed streams

Industrial Regrind: Well-established with 20-30% typical usage

Chemical Recycling: Emerging technologies for depolymerization

Bio-based Alternatives: Developing but not yet commercial at scale

Industry 4.0 Integration

Smart Manufacturing: IoT sensors for predictive maintenance

Digital Twins: Virtual process optimization before physical trials

AI/ML Applications: Defect prediction, parameter optimization

Automated Quality Control: Vision systems for 100% inspection

Material Innovations

Enhanced Grades: Higher heat resistance, improved impact, better flow

Sustainable Formulations: Increased recycled content, bio-based components

Functional Additives: Antimicrobial, static dissipative, conductive grades

Hybrid Materials: ABS composites with enhanced properties

13. Conclusion: The Enduring Engineering Workhorse

ABS injection moulding continues to be a cornerstone of modern manufacturing, offering an unparalleled balance of properties that meet diverse application requirements. Its success lies in the synergy between material formulation and processing expertise—each grade and application demands specific attention to drying requirements, temperature profiles, injection strategies, and tooling design.

As manufacturing evolves toward greater sustainability, digital integration, and advanced applications, ABS remains remarkably adaptable. The future will likely see continued refinement of ABS grades for specific applications, improved recycling technologies, and smarter processing methods that enhance efficiency and quality while reducing environmental impact.

For engineers and manufacturers, mastering ABS injection moulding requires not just following standard parameters, but developing a deep understanding of the material’s behavior under different processing conditions. This knowledge, combined with thoughtful design and precise process control, enables the production of ABS parts that consistently meet the highest standards of quality, performance, and reliability.