The Backbone of Modern Manufacturing: Unveiling the Power of MUD Molds in Injection Molding

The Modular Revolution: How MUD Molds are Reshaping Agile Manufacturing

In the fast-paced world of product development, where time-to-market can make or break a success story, a quiet revolution in injection molding is empowering innovators. The technology, known as Master Unit Die (MUD) molding, is transforming how companies—from ambitious startups to global giants—design, prototype, and manufacture plastic components. By championing modularity over monolithic design, MUD molds are unlocking unprecedented levels of speed, flexibility, and cost-efficiency.

Beyond the “One-Part, One-Mold” Paradigm

Traditional injection molds are custom-built, single-purpose masterpieces. Crafted from solid blocks of steel, they are expensive, often costing $50,000 to $100,000 or more, and can take 12 to 16 weeks to produce. For a new medical device housing, a prototype automotive knob, or a limited-run consumer electronic component, this traditional approach presents a significant barrier.

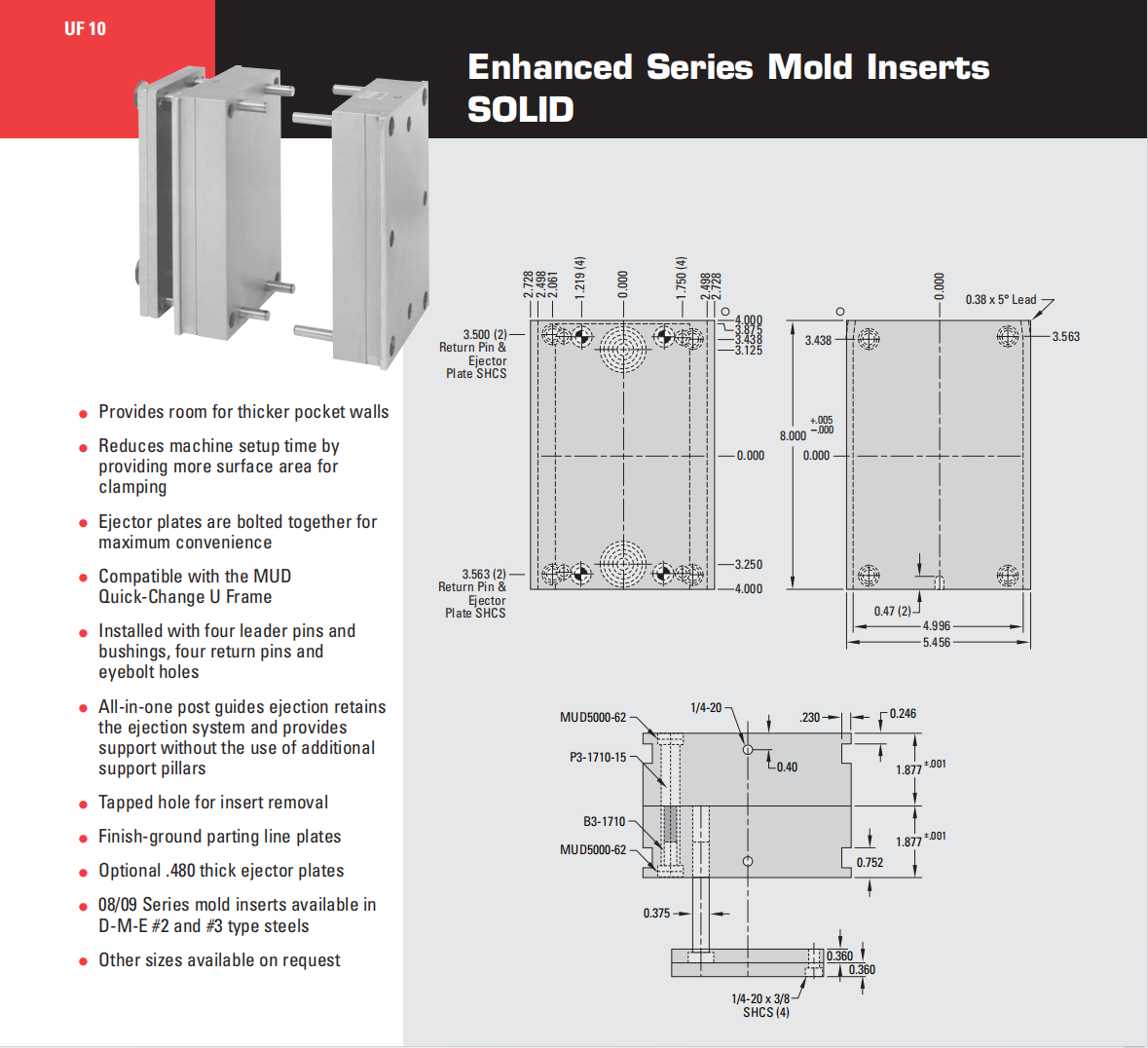

Enter the MUD system. Its core philosophy is elegantly simple: separate the universal from the unique. A MUD system consists of a standardized mold base—a precision-engineered “chassis” containing all the essential components for alignment, cooling, and ejection—and interchangeable cavity and core inserts that define the specific part geometry.

“Think of it like a high-precision Lego system,” explains David Chen, VP of Engineering at AgileMold Solutions. “We invest once in the robust, reusable frame. For each new product, we only need to design and machine the small, specialized blocks—the inserts—that snap into that frame. It changes the entire economics of low and medium-volume production.”

The Tangible Benefits: A Data-Driven Advantage

The advantages of the MUD system are measurable and impactful across the product lifecycle.

| Aspect | Traditional Monolithic Mold | MUD (Modular) Mold | Impact |

|---|---|---|---|

| Initial Lead Time | 12-16 weeks | 3-6 weeks (for inserts only) | ~70% Faster time-to-first-article |

| Initial Tooling Cost | Very High ($50k+) | Significantly Lower (Cost of inserts only) | Up to 60-80% Savings on initial investment |

| Design Change Flexibility | Very Difficult & Costly (modify entire mold) | High (Machine or replace inserts only) | Enables agile iteration and risk reduction |

| Production Suitability | Ideal for very high volumes (Millions) | Optimal for low-to-medium volumes (10k – 500k) | Makes short runs economically viable |

| Maintenance & Repair | Complex, entire mold offline | Simplified, often only insert needs work | Minimizes production downtime |

Where MUD Molds are Driving Innovation

- Rapid Prototyping & Design Validation: Engineers can hold a functional part, made from the intended production material, in weeks rather than months. This accelerates feedback loops and ensures design flaws are caught early.

- Bridge Tooling: MUD molds perfectly fill the gap between prototype approval and the completion of a high-volume, hardened steel production mold, allowing for market seeding and early sales.

- Low-Volume & Specialized Production: For the medical, aerospace, and defense industries, or for legacy part replacement, where production runs may be in the thousands, MUD is the only cost-effective solution.

- Product Families and Customization: A single MUD base can produce multiple variants of a product—different sizes, features, or logos—by simply switching inserts, enabling mass customization.

A Sustainable and Strategic Edge

The benefits extend beyond speed and cost. “The sustainability angle is increasingly important,” notes Maria Rodriguez, a manufacturing analyst. “MUD bases are reused dozens of times, dramatically reducing the raw material and energy consumption associated with building a new mold from scratch for every part. It’s lean manufacturing at the tooling level.”

Furthermore, by lowering the financial risk of new product introduction, MUD technology fosters a more innovative ecosystem. Startups can prototype professionally without burning through capital, and large companies can explore more niche products or market tests.

The Future: Integration with Industry 4.0

The future of MUD is digital and connected. Leading molders are now pairing MUD systems with digital twin technology and IoT sensors. Each insert can have a digital history tracking its cycles, maintenance, and performance. Predictive analytics can schedule insert maintenance before a failure occurs, pushing uptime and quality to new heights.

Conclusion

MUD injection molding is far more than just a type of tool; it is a strategic enabler for agile manufacturing. In an economic climate that demands responsiveness, customization, and prudent investment, the modular approach of MUD molds provides a critical competitive edge. By decoupling the long-term asset (the base) from the product-specific geometry (the insert), it has democratized access to high-quality injection molding, proving that in modern manufacturing, flexibility is the ultimate form of strength.

About the Technology:

Master Unit Die (MUD) is a standardized mold base system governed by industry specifications to ensure compatibility across manufacturers. Major suppliers provide catalog bases in various sizes (e.g., 15″x18″, 18″x24″), allowing molders to build a library of bases for different press tonnages and application needs.