PA injection molding

- Home

- / Material /

- PA injection molding

Nylon (Polyamide) Injection Moulding: Mastering the Versatile Engineering Polymer

1. Introduction: The Engineering Workhorse

Polyamide, universally known as nylon, stands as one of the most versatile engineering thermoplastics, celebrated for its exceptional strength, wear resistance, and thermal stability. First developed by DuPont in the 1930s, nylon has evolved into a family of materials with diverse properties tailored for specific applications. As a semi-crystalline polymer, polyamide presents unique challenges and opportunities in injection moulding, requiring specialized knowledge to harness its full potential.

This comprehensive guide explores the intricate world of PA injection moulding, from its chemical structure to advanced processing techniques. We will examine why nylon remains indispensable in demanding applications ranging from automotive powertrains to industrial machinery, and how proper processing techniques can yield components with exceptional mechanical performance and dimensional stability.

2. Material Science: Understanding the Polyamide Family

Chemical Structure and Classification

Polyamides are characterized by the amide group (–NH–CO–) in their backbone, formed through condensation polymerization. The numbering system indicates the number of carbon atoms in the diamine and diacid components:

Common PA Types and Their Characteristics:

| Type | Full Name | Key Characteristics | Typical Applications |

|---|---|---|---|

| PA6 | Polyamide 6 (Caprolactam) | Good toughness, impact resistance, moderate moisture absorption | Gears, bearings, automotive components |

| PA66 | Polyamide 6,6 (Hexamethylenediamine + Adipic acid) | Higher stiffness, heat resistance, faster crystallization | Electrical connectors, automotive underhood parts |

| PA46 | Polyamide 4,6 | Exceptional heat resistance (HDT up to 290°C) | High-temperature electrical, automotive |

| PA11/PA12 | Polyamide 11/12 (from castor oil/lauryllactam) | Low moisture absorption, excellent dimensional stability | Automotive fuel lines, flexible tubing |

| PPA | Polyphthalamide | Enhanced thermal/chemical resistance | High-performance automotive, industrial |

Reinforced and Modified Grades:

Glass Fiber Reinforced: 15-50% glass fiber for enhanced stiffness and dimensional stability

Mineral Filled: Improved flatness and reduced warpage

Impact Modified: Enhanced toughness for low-temperature applications

Heat Stabilized: For continuous high-temperature exposure

Lubricated: Reduced friction for bearing applications

Physical Properties Overview:

Density: 1.12-1.15 g/cm³ (unreinforced); up to 1.6 g/cm³ (highly filled)

Melting Point: PA6: 220°C; PA66: 260°C; PA12: 178°C

Tensile Strength: 70-90 MPa (unreinforced); up to 200 MPa (glass-filled)

Moisture Absorption: 1.5-3.0% at equilibrium (PA6/66); 0.2-0.5% (PA11/12)

Heat Deflection Temperature: 60-90°C (unfilled); up to 250°C (glass-filled)

3. Material Preparation: The Critical Drying Process

The Imperative of Proper Drying

Polyamides are extremely hygroscopic, requiring meticulous drying to prevent processing issues and ensure optimal properties:

Drying Specifications by PA Type:

| PA Type | Drying Temperature | Drying Time | Target Moisture | Maximum Moisture |

|---|---|---|---|---|

| PA6 | 80-90°C | 4-6 hours | <0.1% | 0.15% |

| PA66 | 80-90°C | 4-6 hours | <0.1% | 0.15% |

| PA46 | 120°C | 4-6 hours | <0.05% | 0.10% |

| PA11/12 | 70-80°C | 3-5 hours | <0.05% | 0.10% |

| Glass-filled | 100-110°C | 6-8 hours | <0.05% | 0.08% |

Drying System Requirements:

Dehumidifying Dryers: Essential for consistent results

Dew Point: -40°C or lower recommended

Hopper Design: Sealed with sufficient residence time

Regrind Drying: Often requires longer times due to increased surface area

Consequences of Improper Drying:

Hydrolytic Degradation: Water causes chain scission during processing

Surface Defects: Splay marks, silver streaks, bubbles

Mechanical Property Loss: Significant reduction in strength and toughness

Dimensional Instability: Excessive post-mould shrinkage and warpage

Poor Appearance: Dull surfaces, inconsistent gloss

Material Handling Protocol:

Storage: Sealed containers with desiccant

Exposure Time: Limit to 30 minutes maximum in humid environments

Moisture Testing: Regular verification using Karl Fischer titration

Regrind Management: Maximum 25% regrind for critical applications

4. Injection Moulding Machine Configuration

Machine Selection Criteria:

Clamping Force: 3-6 tons per square inch of projected area

Injection Capacity: 40-70% of machine maximum

Drive System: Electric or hybrid for precise control

Control System: Capable of managing complex viscosity profiles

Screw Design Requirements:

Type: Compression screw with gradual transition

L/D Ratio: 18:1 to 22:1 (shorter than for some thermoplastics)

Compression Ratio: 3.0:1 to 3.5:1 (higher for uniform melting)

Check Valve: Sliding ring type with minimal resistance

Screw Tip: Mixing elements for filled grades

Barrel and Nozzle Specifications:

Barrel Zones: Minimum 3 zones with PID control

Temperature Control: ±3°C accuracy required

Nozzle Type: Open nozzle with temperature control

Shot Size: Consistent cushion of 3-6mm recommended

Special Considerations:

Corrosion Resistance: Nickel-plated screws/barrels for some reinforced grades

Wear Protection: Hardened components for abrasive filled materials

Cleaning Protocol: Proper purging between material changes

5. Processing Parameters and Optimization

Temperature Settings by PA Type:

| PA Type | Rear Zone | Middle Zone | Front Zone | Nozzle | Melt Temp | Mould Temp |

|---|---|---|---|---|---|---|

| PA6 | 220-240°C | 240-260°C | 250-270°C | 250-270°C | 240-280°C | 60-90°C |

| PA66 | 260-280°C | 280-295°C | 290-305°C | 290-305°C | 280-310°C | 70-120°C |

| PA46 | 280-300°C | 300-320°C | 310-330°C | 310-330°C | 290-330°C | 100-140°C |

| PA11 | 190-210°C | 210-230°C | 220-240°C | 220-240°C | 200-250°C | 40-70°C |

Injection Phase Parameters:

Injection Speed: Fast to very fast (prevents premature freezing)

Injection Pressure: 800-1400 bar (higher for reinforced grades)

Switchover: 95-98% cavity fill by volume or pressure-based

Back Pressure: 5-20 bar for melt homogenization

Holding/Packing Phase:

Pressure: 40-60% of injection pressure

Time: Until gate freeze (typically 5-15 seconds)

Function: Critical for dimensional control in crystalline materials

Cooling Strategy:

Cooling Time: 20-40 seconds per mm of wall thickness

Ejection Temperature: Below 100°C for most grades

Cycle Time Optimization: Balance between cooling and crystallization

Special Processing Techniques:

Gas-Assisted Moulding: For thick sections to reduce sink marks

Sequential Moulding: For large parts to optimize filling

In-Mould Annealing: For stress relief in high-performance applications

6. Tooling Design for Polyamide Moulding

Mould Material Selection:

Production Moulds: Pre-hardened steels (P20, 4140) or hardened tool steels

Surface Hardness: 48-52 HRC for abrasion resistance

Cavity Finish: SPI B-1 to C-3 depending on application

Corrosion Protection: Nickel plating for moisture protection

Runner System Design:

Cold Runners: Full round, 6-10mm diameter minimum

Hot Runners: Externally heated with precise temperature control

Balancing: Critical for multi-cavity moulds

Gate Types:

Edge Gates: Most common, easy to trim

Diaphragm Gates: For cylindrical parts

Hot Tips: For cosmetic applications

Cooling System Design:

Channel Design: Follow part contours closely

Temperature Control: Separate circuits for cores and cavities

Uniformity: ±5°C across mould surface maximum

Baffles/Bubbler: For deep cores

Venting Requirements:

Vent Depth: 0.015-0.030mm

Vent Width: 6-10mm

Location: End of fill and weld line areas

Importance: Prevents burning and incomplete filling

Ejection System:

Ejector Pins: Larger diameter for lower surface pressure

Stripper Plates: For tubular parts

Ejection Force: Higher than for amorphous materials due to shrinkage

7. Part Design Guidelines for Polyamide

Wall Thickness Principles:

General Range: 1.0-3.0mm (optimal: 1.5-2.0mm)

Uniformity: Critical to prevent warpage (max variation: 20%)

Thick Sections: Core out to minimize shrinkage differences

Minimum Thickness: 0.5mm possible with optimized processing

Rib and Boss Design:

Rib Thickness: 40-60% of adjacent wall

Rib Height: Maximum 3 times wall thickness

Boss Design: Should be cored and connected with ribs

Draft Angles: 1-2° per side minimum

Corner Design:

Internal Radii: Minimum 0.5 times wall thickness

External Radii: Internal radius plus wall thickness

Benefits: Reduces stress concentration, improves flow

Draft Angles:

Standard Parts: 1-2° per side

Textured Surfaces: Add 1° per 0.025mm texture depth

Deep Cores: Additional 0.5° per 25mm depth

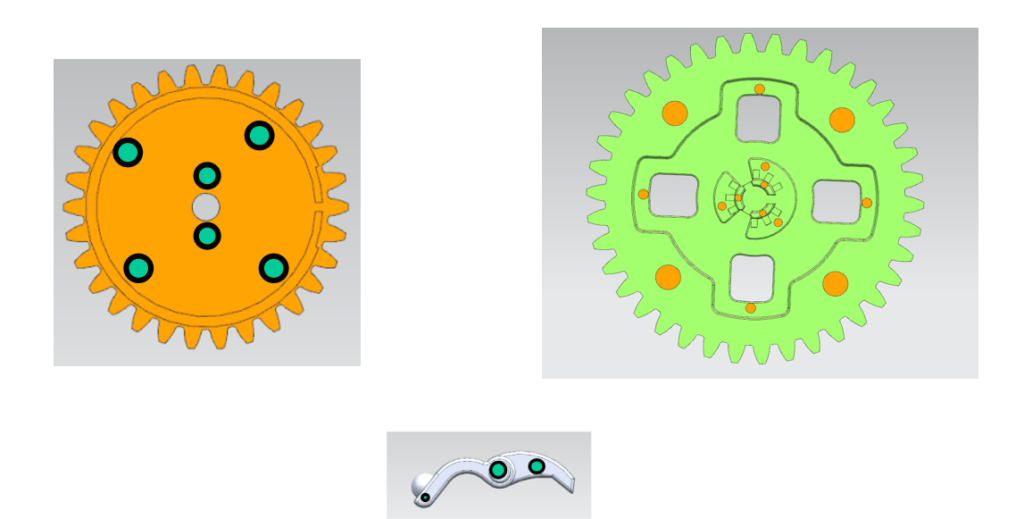

Gear and Bearing Design:

Tooth Design: Consider shrinkage in mold design

Clearances: Account for moisture absorption effects

Mounting Bosses: Design for press fits considering creep

8. Crystallinity and Its Impact on Processing

Understanding Nylon Crystallinity:

Semi-Crystalline Nature: 20-40% crystalline regions typically

Crystallization Rate: PA66 > PA6 > PA12

Factors Affecting Crystallinity: Cooling rate, nucleation, molecular weight

Processing Effects on Crystallinity:

Mould Temperature: Higher temperatures promote higher crystallinity

Cooling Rate: Slow cooling increases crystallinity

Nucleating Agents: Increase crystallization rate and uniformity

Property Implications:

Higher Crystallinity: Increased strength, stiffness, chemical resistance

Lower Crystallinity: Improved toughness, transparency, dimensional stability

Dimensional Effects: Crystalline shrinkage (1.5-2.5%) vs. amorphous shrinkage (0.5-1.0%)

Controlling Crystallization:

Mould Temperature Control: Precise control for consistent properties

Annealing: Post-mould heat treatment to increase crystallinity

Nucleated Grades: For faster cycles and improved properties

9. Moisture Management: Before and After Moulding

Post-Mould Conditioning:

Purpose: Achieve equilibrium moisture content for dimensional stability

Methods:

Water Immersion: 60-70°C water for several hours

Steam Conditioning: Faster but requires careful control

Humidity Chamber: Controlled environment (50% RH, 23°C)

Conditioning Times: 24-48 hours typically for PA6/66

Dimensional Changes with Moisture:

PA6/66: Expand 0.2-0.3% per 1% moisture gain

PA11/12: Expand 0.1-0.15% per 1% moisture gain

Design Consideration: Allow for moisture expansion in assemblies

Conditioning Protocols by Application:

| Application | Conditioning Method | Target Moisture | Key Benefits |

|---|---|---|---|

| Precision Gears | Hot water immersion | 2.0-2.5% | Dimensional stability, toughness |

| Electrical Parts | Humidity chamber | 1.0-1.5% | Stable electrical properties |

| Structural | Controlled environment | Equilibrium | Consistent mechanical properties |

| Dry Applications | Minimal conditioning | <0.5% | Maximum stiffness |

10. Troubleshooting Common Nylon Defects

| Defect | Root Causes | Corrective Actions |

|---|---|---|

| Splay/Silver Streaks | Moisture contamination, overheating | Verify drying (<0.1%), reduce melt temperature |

| Weld Lines | Low melt temperature, slow injection | Increase temperature 10-20°C, increase injection speed |

| Sink Marks | Insufficient packing, thick sections | Increase holding pressure/time, redesign thick areas |

| Warpage | Non-uniform cooling, differential shrinkage | Improve cooling uniformity, adjust gate location |

| Brittleness | Over-drying, excessive moisture, degradation | Optimize drying conditions, check material freshness |

| Flash | Excessive injection pressure, worn tooling | Reduce pressure, repair tool, increase clamp force |

| Dimensional Variation | Inconsistent moisture content, process variation | Standardize conditioning, implement SPC |

| Poor Surface Finish | Low mould temperature, contaminated material | Increase mould temperature, clean material handling |

Material-Specific Issues:

Degradation: Yellowing and property loss from overheating

Crystallinity Variation: Inconsistent properties from uneven cooling

Moisture Sensitivity: Property changes with environmental exposure

11. Advanced Processing Techniques

Multi-Material Moulding:

Nylon/TPE Combinations: For seals and gaskets

Nylon/Nylon Combinations: Different colors or properties

Overmoulding: For enhanced functionality

Gas-Assisted Injection Moulding:

Benefits: Weight reduction, reduced sink marks

Applications: Handles, panels, thick-section parts

Challenges: Consistent channel formation

In-Mould Assembly:

Integrated Hinges: Using nylon’s flexibility

Snap-fits: Designed for in-mould engagement

Benefits: Reduced assembly operations

Microcellular Foam Moulding:

Benefits: Weight reduction, reduced warpage

Applications: Large panels, structural parts

Considerations: Surface quality, strength reduction

High-Speed Moulding for Thin Walls:

Applications: Electrical connectors, consumer electronics

Requirements: Fast injection, precise temperature control

Benefits: Reduced cycle times

12. Quality Control and Testing

Process Monitoring:

Key Parameters: Melt temperature, moisture content, cushion consistency

Statistical Process Control: For dimensional and weight consistency

Real-time Monitoring: Pressure and temperature sensors

Material Testing:

Moisture Analysis: Karl Fischer titration for accurate measurement

Rheological: Melt Flow Rate (ASTM D1238)

Mechanical:

Tensile (ASTM D638)

Impact (ASTM D256)

Flexural (ASTM D790)

Thermal:

DSC for melting point and crystallinity

TGA for thermal stability

HDT (ASTM D648)

Dimensional: Shrinkage measurement under controlled conditions

Part Validation:

Dimensional: CMM measurement at controlled humidity

Performance: Functional testing under application conditions

Environmental: Heat aging, chemical resistance, humidity cycling

Long-term: Creep and fatigue testing for critical applications

13. Industry Applications and Case Studies

Automotive Industry:

Underhood Components: Intake manifolds, engine covers, cooling parts

Powertrain: Gears, bearings, bushings

Fuel Systems: Lines, connectors, housings

Benefits: Weight reduction, chemical resistance, heat stability

Electrical and Electronics:

Connectors: Miniaturized components with high pin counts

Circuit Breakers: Arc resistance and thermal stability

Enclosures: Flame retardant grades for safety

Consumer Products:

Power Tools: Housings and gears

Sporting Goods: Strength and fatigue resistance

Apparel: Fibers and mechanical components

Industrial Applications:

Gears and Bearings: Wear resistance and self-lubrication

Pumps and Valves: Chemical resistance

Conveyor Components: Strength and durability

Medical Applications:

Surgical Instruments: Autoclavable grades

Dental Devices: Precision and biocompatibility

Equipment Housings: Cleanability and durability

14. Sustainability and Future Directions

Recycling Technologies:

Mechanical Recycling: Limited by property degradation

Chemical Recycling:

Hydrolysis: Back to monomers

Ammonolysis: Alternative depolymerization

Pyrolysis: For chemical feedstocks

Closed-Loop Systems: Developing for automotive and textile applications

Bio-based Nylons:

PA11: From castor oil (100% bio-based)

PA610: Partially bio-based (sebacic acid from castor oil)

PA410: High bio-content with good properties

Performance: Comparable to petroleum-based nylons

Energy Efficiency:

All-Electric Machines: Precise control for energy savings

Process Optimization: Reduced cycle times through simulation

Heat Recovery: From cooling systems

Emerging Technologies:

Nanocomposites: Enhanced properties with nano-fillers

Self-reinforcing Nylons: In-situ polymerization for superior properties

Smart Nylons: Integrated sensors or functional properties

15. Conclusion: Mastering the Nylon Challenge

Polyamide injection moulding represents a sophisticated balance of material science, process engineering, and practical experience. Its successful processing demands respect for the material’s unique characteristics—particularly its hygroscopic nature and crystalline behavior—combined with meticulous attention to every aspect of the manufacturing process.

The future of nylon lies in developing more sustainable versions while maintaining or enhancing its exceptional performance characteristics. Advances in bio-based nylons, improved recycling technologies, and energy-efficient processing will ensure nylon remains relevant in an increasingly environmentally conscious market.

For manufacturers, success with nylon requires:

Deep Material Understanding: Knowledge of different PA types and their behaviors

Precise Process Control: Consistent execution of optimized parameters

Robust Quality Systems: Monitoring and controlling key variables

Application Knowledge: Understanding end-use conditions and requirements

As applications become more demanding—whether in higher temperatures, greater mechanical loads, or stricter environmental requirements—nylon injection moulding professionals must continue to innovate and refine their techniques to meet these challenges.