PE injection molding

- Home

- / Material /

- PE injection molding

A Comprehensive Guide to Polyethylene (PE) Injection Moulding: From Fundamentals to Advanced Applications

1. Introduction: The World’s Most Versatile Polymer

Polyethylene (PE) holds the distinction of being the most produced plastic globally, with annual production exceeding 100 million tons. Its remarkable versatility stems from its relatively simple chemical structure, which can be engineered into various densities and molecular configurations. While commonly associated with blow-moulded bottles and extruded films, injection moulding represents a crucial processing method for PE, enabling the production of durable, complex parts across virtually every industry sector.

From household containers and children’s toys to industrial components and automotive parts, PE injection moulding combines material accessibility with processing efficiency. This comprehensive guide explores the technical nuances of polyethylene injection moulding, covering material variants, processing parameters, design considerations, and emerging trends that are shaping the future of this essential manufacturing process.

2. Material Science: Understanding Polyethylene Variants

Polyethylene’s performance characteristics are primarily determined by its density and branching structure, leading to three main commercial grades:

Low-Density Polyethylene (LDPE)

Structure: Highly branched polymer chains creating a less compact structure

Density: 0.910-0.925 g/cm³

Properties: Excellent flexibility, clarity, and impact strength; good chemical resistance

Typical Applications: Flexible lids, squeezable bottles, laboratory equipment, protective caps

Processing Notes: Lower melting point (105-115°C), relatively easy flow characteristics

High-Density Polyethylene (HDPE)

Structure: Linear chains with minimal branching, allowing tight packing

Density: 0.941-0.965 g/cm³

Properties: High stiffness, tensile strength, and chemical resistance; good moisture barrier properties

Typical Applications: Rigid containers, industrial parts, crates, pallets, food handling equipment

Processing Notes: Higher melting point (120-130°C), requires more injection pressure than LDPE

Linear Low-Density Polyethylene (LLDPE)

Structure: Controlled short-chain branching

Density: 0.915-0.925 g/cm³

Properties: Superior toughness, puncture resistance, and environmental stress crack resistance compared to LDPE

Typical Applications: Thin-walled containers, lids, caps, and applications requiring high impact strength

Processing Notes: Processes at temperatures between LDPE and HDPE

Specialty Grades:

UHMWPE: Ultra-high molecular weight PE with exceptional wear resistance

Cross-linked PE: Improved temperature resistance and dimensional stability

Bio-based PE: Derived from renewable resources like sugarcane

3. The Injection Moulding Process for PE: Technical Considerations

Material Preparation and Drying

Unlike many engineering plastics, most polyethylene grades require minimal drying before processing. However, proper material handling is essential:

Moisture Content: Typically <0.1% moisture acceptable for standard grades

Regrind Usage: PE generally tolerates 20-30% regrind without significant property degradation

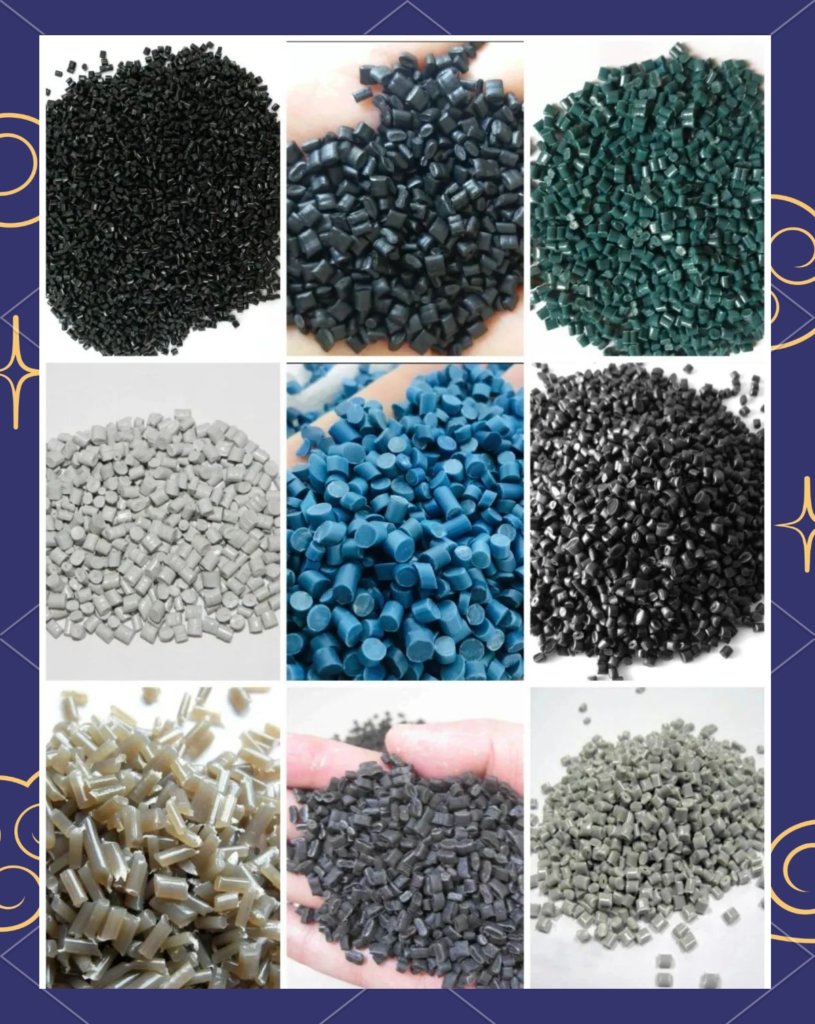

Colorant Addition: Excellent compatibility with most pigments and masterbatches

Machine Configuration Requirements

Screw Design: Standard general-purpose screws with L/D ratio of 20:1 to 24:1 are suitable

Nozzle Type: Open nozzle or shut-off nozzle both acceptable depending on application

Clamping Force: Moderate requirements (2-5 tons per square inch of projected area)

Processing Parameters by Grade:

| Parameter | LDPE | HDPE | LLDPE |

|---|---|---|---|

| Melt Temperature | 160-220°C | 180-260°C | 170-240°C |

| Mould Temperature | 20-50°C | 30-70°C | 20-60°C |

| Injection Pressure | Medium (500-1000 bar) | High (700-1400 bar) | Medium-High (600-1200 bar) |

| Injection Speed | Medium-Fast | Medium | Fast |

| Cooling Time | Short (10-30 sec) | Medium (20-60 sec) | Short-Medium (15-40 sec) |

4. Critical Processing Parameters and Their Optimization

Temperature Management

Barrel Zones:

Rear zone: 160-180°C (HDPE) or 140-160°C (LDPE)

Middle zones: 180-220°C (HDPE) or 160-200°C (LDPE)

Front zone/nozzle: 200-240°C (HDPE) or 180-220°C (LDPE)

Thermal Degradation: PE is relatively stable but can degrade above 300°C, leading to odor and discoloration

Pressure and Speed Optimization

Packing Pressure: Critical for minimizing shrinkage and sink marks

Holding Time: Should continue until gate freeze-off (typically 5-15 seconds)

Speed-Pressure Balance: Higher speeds generally reduce viscosity (shear thinning effect)

Cooling System Design

PE’s relatively high shrinkage rate (1.5-4.0%) demands efficient, uniform cooling

Conformal cooling channels often provide benefits for complex parts

Coolant temperature control within ±2°C recommended

5. Part Design Guidelines for Polyethylene

Wall Thickness Considerations

Recommended Range: 0.8mm to 6.0mm

Uniformity: Critical to prevent warpage and sink marks

Transition Areas: Gradual changes in thickness (3:1 maximum ratio)

Draft Angles

Minimum: 1° per side for shallow features

Recommended: 1.5-2° for textured surfaces

Deep Draw Parts: 3° or more to facilitate ejection

Rib and Boss Design

Rib Thickness: 40-60% of adjacent wall thickness

Rib Height: Maximum 3 times wall thickness

Boss Design: Should be cored out to maintain uniform wall thickness

Corner Radii

Internal Corners: Minimum radius of 0.5 times wall thickness

External Corners: Radius should equal internal radius plus wall thickness

Living Hinges

Thickness: 0.25-0.50mm

Material Flow: Must be parallel to hinge axis

Design: Should incorporate generous radii at hinge extremities

6. Tooling Design Specifics for PE

Mould Material Selection

Production <100,000 cycles: Pre-hardened steels (P20, NAK80)

Production >1,000,000 cycles: Hardened tool steels (H13, S7)

Prototype Moulds: Aluminum or soft steels

Gate Design

Edge Gates: Most common, easy to trim

Tab Gates: Help reduce jetting in thin-walled parts

Hot Runner Systems: Increasingly popular for multi-cavity production

Gate Size: Typically 0.5-1.0mm thickness, width depends on part geometry

Venting Requirements

PE’s rapid injection can trap air; adequate venting is crucial

Vent Depth: 0.015-0.030mm for HDPE, 0.020-0.040mm for LDPE

Location: At end of fill and weld line areas

Surface Finishes

Texturing: PE accommodates a wide range of textures

Polishing: SPI A-1 to B-3 finishes common

Ejection: Higher gloss increases ejection resistance

7. Troubleshooting Common PE Injection Moulding Defects

| Defect | Possible Causes | Corrective Actions |

|---|---|---|

| Sink Marks | Insufficient packing, excessive wall thickness, high melt temperature | Increase holding pressure/time, redesign thick sections, lower melt temp |

| Warpage | Non-uniform cooling, differential shrinkage, improper gate location | Improve cooling uniformity, adjust mould temperature, optimize gate position |

| Jetting | Gate too small, injection speed too high, melt temperature too low | Enlarge gate, reduce injection speed, increase melt temperature |

| Short Shots | Insufficient material, low melt temperature, inadequate venting | Check material volume, increase temperature, add/clean vents |

| Weld Lines | Multiple flow fronts, low melt temperature, poor gate location | Increase temperature and injection speed, relocate gates, improve venting at weld areas |

| Flash | Excessive injection pressure, worn tooling, insufficient clamping force | Reduce pressure, repair tool, increase clamp force |

| Poor Ejection | Insufficient draft, high shrinkage on cores, vacuum formation | Increase draft angles, polish cores, add air ejection or stripper plates |

Material-Specific Issues:

Environmental Stress Cracking: Particularly relevant for HDPE in contact with certain chemicals

Post-Mould Shrinkage: Continues for 24-48 hours after ejection

Weld Line Weakness: More pronounced in HDPE than in LDPE

8. Advanced Processing Techniques for Polyethylene

Multi-Material/Overmoulding

PE often serves as substrate for TPE/TPR overmoulding

Applications: Soft-grip handles, seals, decorative elements

Compatibility considerations critical for adhesion

Gas-Assisted Injection Moulding

Benefits: Reduced weight, elimination of sink marks, lower clamp tonnage

Particularly effective for thick-sectioned PE parts

Common applications: Handles, furniture components, automotive trim

In-Mould Decoration/Labelling

Growing application for PE containers and lids

Allows high-quality graphics on curved surfaces

Eliminates secondary decoration operations

Foam Injection Moulding (MuCell®)

Microcellular foam structure

Benefits: Weight reduction, reduced sink marks, dimensional stability

Applications: Large panels, thick-section parts

9. Sustainability and Recycling in PE Injection Moulding

Post-Consumer Recycled (PCR) Content

Processing Challenges: Variable melt flow, potential contamination, color limitations

Equipment Modifications: Improved filtration, vented barrels for volatile removal

Quality Control: Enhanced monitoring for consistency

Design for Recyclability

Material Consolidation: Using single polymer families where possible

Easy Disassembly: Designing for end-of-life separation

Marking and Identification: Following SPI resin identification codes

Biobased Polyethylene

Derived from renewable resources (typically sugarcane ethanol)

Chemically identical to petroleum-based PE

Drop-in replacement with identical processing parameters

Energy Efficiency Improvements

All-electric machines reducing energy consumption by 50-70%

Heat recovery systems

Optimized cycle times through advanced process control

10. Future Trends and Innovations

Industry 4.0 Integration

IoT sensors for real-time process monitoring

Predictive maintenance based on material and machine data

AI-driven parameter optimization

Advanced Materials Development

Enhanced nucleation for faster cycle times

Self-reinforcing PE grades

PE composites with natural fibers

Digital Manufacturing Technologies

3D printed conformal cooling inserts

Digital twin simulation for first-time-right moulding

Augmented reality for maintenance and troubleshooting

Circular Economy Initiatives

Chemical recycling to virgin-quality PE

Advanced sorting technologies (AI, NIR, markers)

Standardized recycled content specifications

11. Conclusion: The Enduring Relevance of PE Injection Moulding

Polyethylene injection moulding remains a cornerstone of global manufacturing, combining material versatility with processing efficiency. Its continued evolution—driven by sustainability imperatives, digital transformation, and material innovations—ensures its relevance for decades to come. Success in PE injection moulding requires a holistic understanding spanning material science, process engineering, tool design, and application requirements.

As the industry moves toward more sustainable practices and smarter manufacturing systems, polyethylene’s fundamental advantages—chemical resistance, processing flexibility, and cost-effectiveness—position it as a material of choice for both traditional and emerging applications. The future of PE injection moulding lies in balancing these inherent advantages with environmental responsibility and technological innovation, creating value across the entire product lifecycle from design to end-of-life recovery.